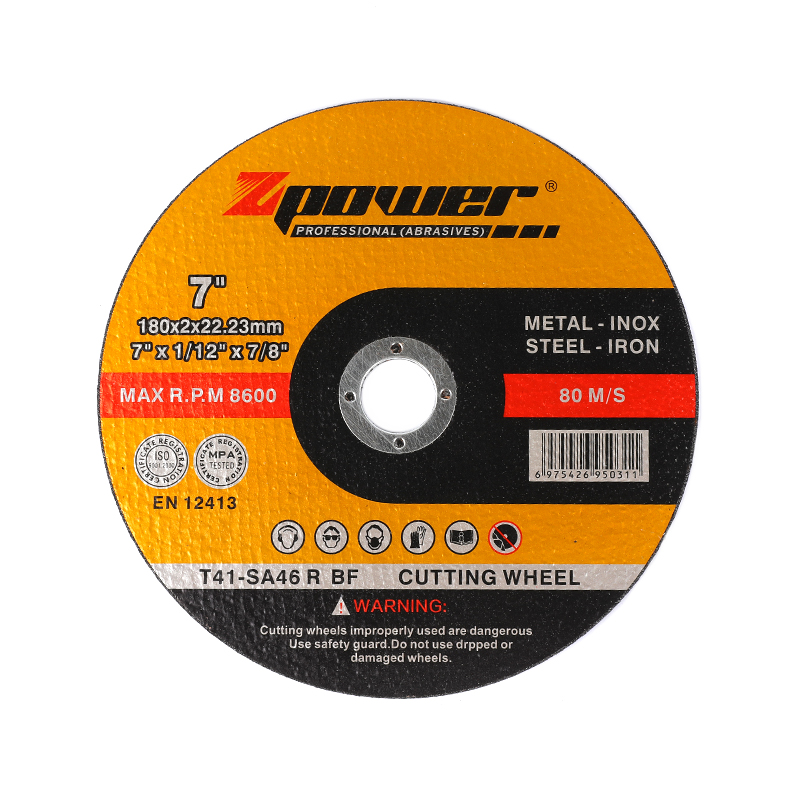

Abrasive Cutting Wheel For Metal

Our Abrasive Cutting Wheel for Metal employs production techniques and high-quality auxiliary raw materials to deliver performance. Featuring uniform grit distribution, the wheel boasts nice tensile, impact, and bending strength, ensuring outstanding cutting efficiency. It outperforms traditional metal saws by cutting faster, generating less heat, and producing surface finishes. This makes it an ideal choice for industries involved in grinding and cutting metal profiles and pipes, providing a reliable and safe solution for various applications.

Features

1. Versatile Cutting Capability: Designed to handle a range of hard materials, including hardened steel, metal carbide, and brittle non-metallic materials. Its robust construction ensures effective cutting and processing even in demanding conditions.

2. Innovative Ring Hole Design: The unique ring hole design enhances clamping strength, reduces chipping, and provides more stable grinding. This innovation improves the wheel’s overall performance and durability.

3. Enhanced Service Life: The wheel is precision-formed and subjected to high-temperature firing, which significantly extends its service life. This high-quality manufacturing process ensures long-lasting performance and reliability.

4. Efficient Heat Management: The cutting wheel generates less heat compared to traditional methods, reducing thermal stress on both the wheel and the workpiece. This results in cleaner cuts and longer wheel life.

5. High Safety Standards: Engineered with safety in mind, our abrasive cutting wheel adheres to stringent safety standards, reducing risks during operation and providing peace of mind.

6. Applications: Widely used in various industries for cutting and grinding metal profiles, pipes, and other hard materials, making it a versatile tool for professionals seeking efficiency and precision.

Additional Advantages

1. Precision and Consistency: The uniform grit distribution ensures consistent cutting performance and precision, reducing the need for frequent adjustments or replacements. This reliability translates to smoother and more accurate results in every application.

2. Reduced Downtime: The enhanced durability and extended service life of our cutting wheel mean less frequent replacements and reduced downtime, allowing for uninterrupted productivity and cost savings in the long run.

3. Compatibility: Our cutting wheel is designed to be compatible with a variety of cutting and grinding equipment, making it a versatile choice for both handheld and stationary tools. This adaptability ensures that you can integrate it seamlessly into your existing setup.

4. Environmentally Friendly: The advanced manufacturing processes used in our cutting wheel are designed with environmental considerations in mind. By optimizing material usage and reducing waste, we contribute to a more sustainable approach to industrial cutting solutions.

5. User-Friendly Operation: The reduced heat generation and fewer chipping contribute to a smoother cutting experience, which is easier on both the operator and the equipment. This user-friendly nature enhances overall safety and efficiency during operation.

6. Quality Assurance: Each cutting wheel undergoes rigorous quality control checks to ensure it meets high standards of performance and safety. Our commitment to quality guarantees that you receive a reliable and effective product every time.

With its combination of advanced features and practical benefits, our Abrasive Cutting Wheel for Metal is an essential tool for professionals and craftsmen who demand high performance and reliability in their cutting and grinding tasks.

Specifications

|

Model |

355×4.0×25.4mm (7"x1/6"x1) |

|

Packing Quantity |

5PCS/Blister pack, 25PCS/Carton |

|

Color box size |

36x36x9cm |

|

G.W. |

19kg |

|

N.W. |

18kg |

|

Material |

Alumina abrasive |

|

Cooperation Projects |

OEM/ODM |

|

Trademark |

Zpower/Free design trademark on behalf of processing |

|

MOQ |

10000-50000PCS |

|

Payment Method |

T/T, L/C, Trade Assurance |

|

Loading port |

Yiwu/Ningbo/Shanghai Port |

|

Sample |

Provide free samples not include shipping |

|

Delivery date |

15-45 days after receiving the deposit |

KEEP IN TOUCH

-

Grinding wheels are often treated as routine workshop items, yet their performance depends heavily on how they are made. From cutting stability to wear behavior, many factors are determined long befo...

READ MORE -

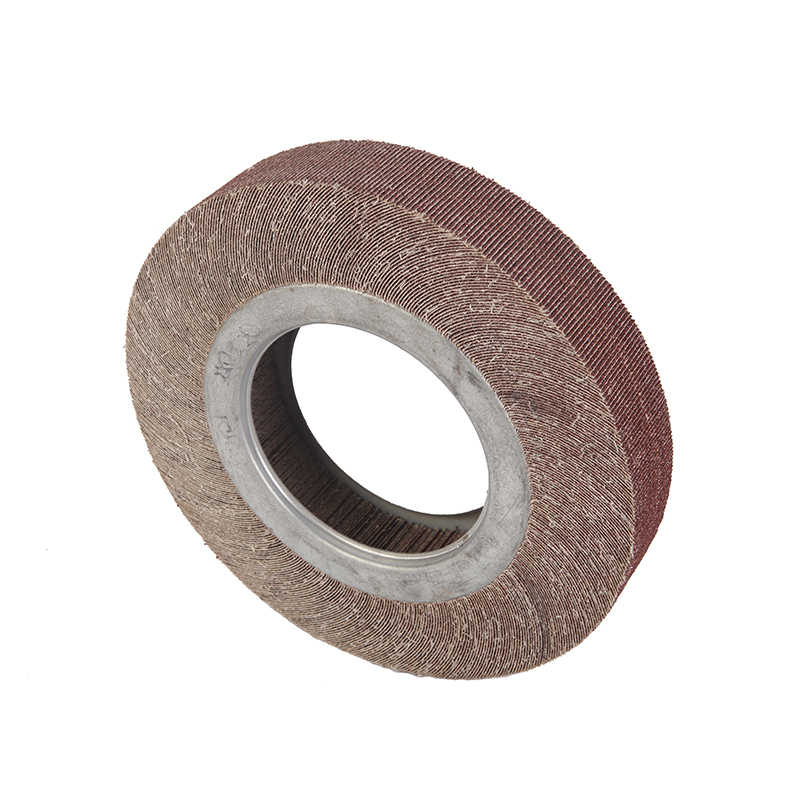

Flap wheels are widely used in metalworking, woodworking, and surface finishing tasks. From smoothing weld seams to preparing surfaces for coating, they play a quiet but important role in many indust...

READ MORE -

Flap discs are widely used in metal fabrication, construction, and maintenance work. They are valued for their ability to grind, blend, and finish surfaces in a single step. Behind these abrasive too...

READ MORE -

Grinding wheels play a steady role in metalworking, fabrication, and surface finishing. Among various abrasive products, alumina grinding wheels are widely used for their stable performance across di...

READ MORE

Eng

Eng  عربى

عربى