How Does an Alumina Grinding Wheel Factory Support Industrial Grinding Needs?

2026.01.09

2026.01.09

Industry News

Industry News

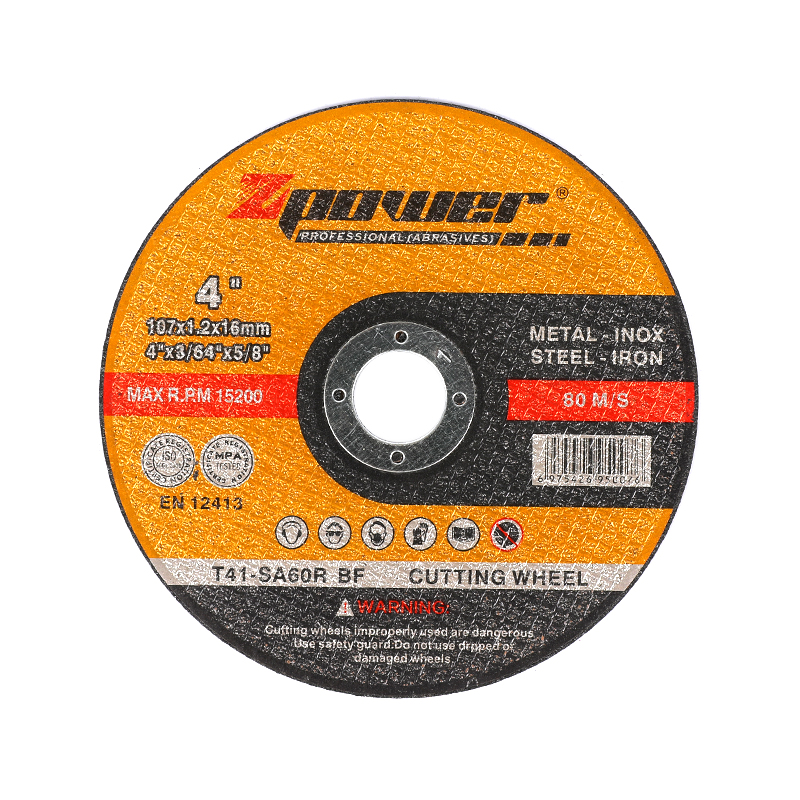

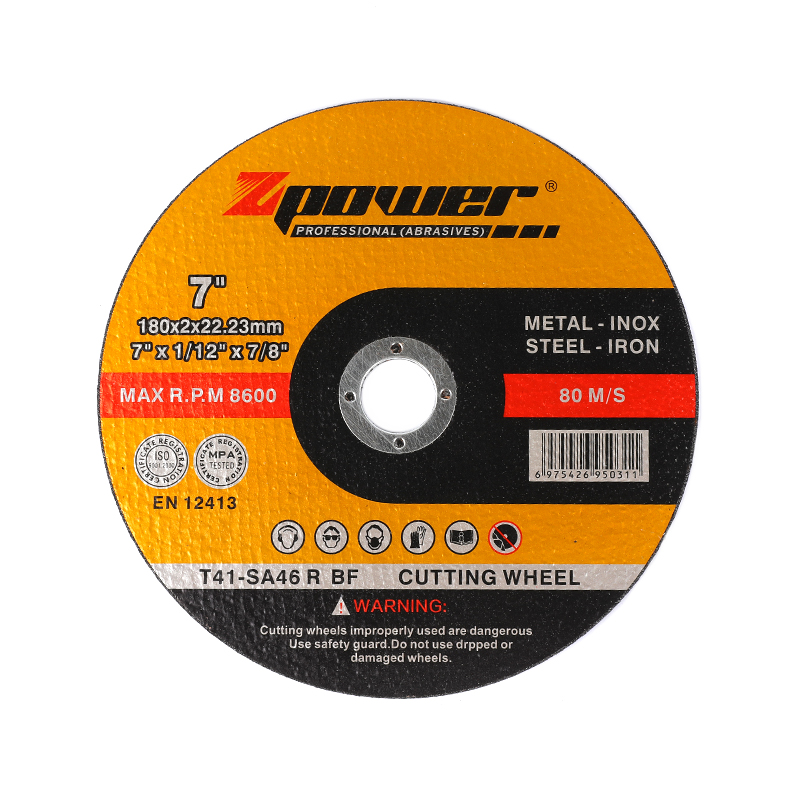

Grinding wheels play a steady role in metalworking, fabrication, and surface finishing. Among various abrasive products, alumina grinding wheels are widely used for their stable performance across different materials. Behind these tools, an Alumina Grinding Wheel Factory is responsible for transforming raw abrasive grains into practical products that meet daily industrial demands.

The Core Role of an Alumina Grinding Wheel Factory

An Alumina Grinding Wheel Factory focuses on producing wheels designed for cutting, grinding, and surface preparation. These factories serve industries such as machinery manufacturing, automotive repair, construction, and tool processing. Their task is not only shaping grinding wheels but also ensuring consistency in structure, bonding strength, and abrasive distribution.

Factories must balance production efficiency with product reliability. This balance helps grinding wheels perform steadily during extended use without unexpected wear patterns.

Raw Materials and Abrasive Preparation

Alumina, also known as aluminum oxide, is the primary abrasive material used in these wheels. It is selected for its hardness and suitability for grinding steel and other metals. In an Alumina Grinding Wheel Factory, alumina grains are carefully graded by size to match different grinding requirements.

The bonding materials, whether resin or vitrified bonds, are equally important. They hold the abrasive grains together while allowing controlled wear. Proper material preparation ensures the grinding wheel maintains its shape and cutting ability during operation.

Manufacturing and Forming Process

The production process inside an Alumina Grinding Wheel Factory follows several structured steps:

- Mixing alumina grains with bonding agents

- Molding the mixture into specific wheel shapes

- Curing or firing the wheels under controlled conditions

- Trimming, balancing, and surface finishing

Each step affects how the grinding wheel performs under pressure. Factories monitor temperature, pressure, and timing closely to maintain stable quality across batches.

Design for Practical Performance

Grinding wheels are designed based on real working conditions. An Alumina Grinding Wheel Factory considers factors such as wheel hardness, grain size, and bond type to suit different applications. For rough grinding, coarser grains may be used, while finer grains support smoother surface finishing.

Design teams often test wheels on actual machines to observe vibration, heat buildup, and wear rate. These tests help refine specifications before mass production begins.

Quality Control and Daily Inspection

Quality control is an ongoing process rather than a single step. In an Alumina Grinding Wheel Factory, inspections take place throughout production. This includes checking wheel dimensions, balance, and structural integrity. Sample wheels may undergo grinding tests to confirm performance consistency.

These checks help reduce defects and ensure that products delivered to customers meet agreed standards. Stable quality also helps users maintain safer working conditions.

Customization and Market Adaptation

Different industries require different grinding solutions. Many factories offer customization options such as wheel diameter, thickness, hole size, and bonding type. An Alumina Grinding Wheel Factory serving international markets may adjust specifications to match regional machinery or operating habits.

Customization does not always require complex redesign. Small changes in grain size or bonding formula can adapt a wheel for a new application while keeping production efficient.

Value for Buyers and Distributors

Working with a reliable Alumina Grinding Wheel Factory provides buyers with more than just products. Buyers benefit from consistent supply, technical guidance, and predictable specifications. This stability simplifies purchasing decisions and helps distributors manage inventory more effectively.

Long-term cooperation also allows factories to better understand user feedback and refine products over time.

An Alumina Grinding Wheel Factory plays a practical role in supporting industrial grinding operations. From material preparation to forming, testing, and customization, each stage contributes to how grinding wheels perform in real working environments. Understanding these processes helps buyers select products that align with their operational needs and long-term use expectations.

Eng

Eng  عربى

عربى