Why Do Manufacturing Details Matter in a Flap Wheel Factory?

2026.01.23

2026.01.23

Industry News

Industry News

Flap wheels are widely used in metalworking, woodworking, and surface finishing tasks. From smoothing weld seams to preparing surfaces for coating, they play a quiet but important role in many industries. Behind these abrasive tools, a Flap Wheel Factory handles the process of turning raw materials into practical products designed for consistent use.

The Role of a Flap Wheel Factory

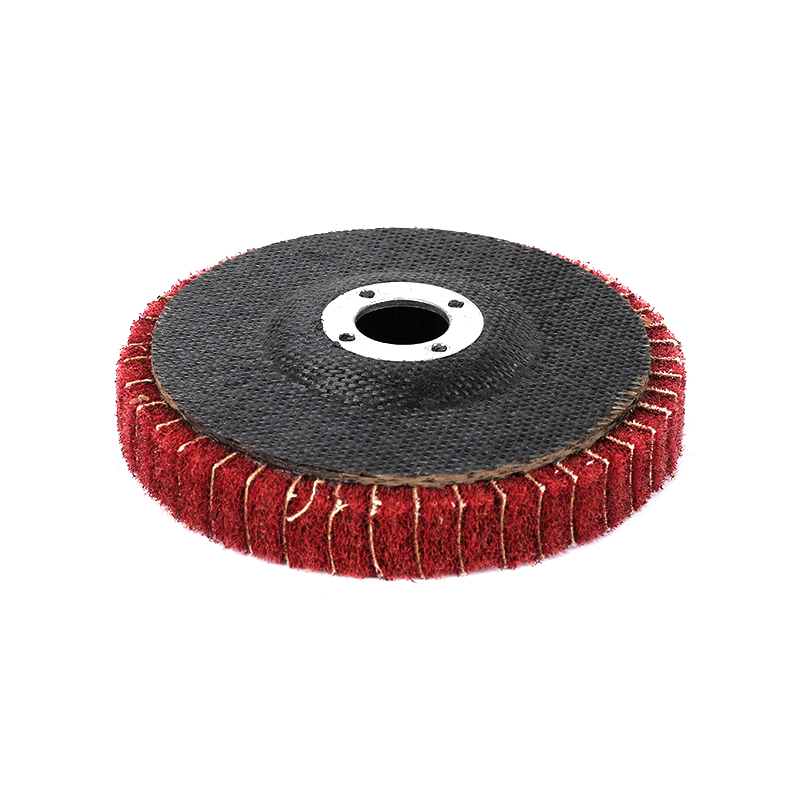

A Flap Wheel Factory specializes in producing abrasive wheels made of overlapping coated flaps arranged around a central hub. These tools are designed to grind, blend, and finish surfaces in a controlled way. The factory's responsibility goes beyond simple assembly; it includes material selection, bonding methods, and performance testing.

Manufacturers aim to balance cutting ability with durability. This balance allows flap wheels to remove material while maintaining a relatively smooth finish, making them suitable for both rough preparation and fine surface work.

Raw Materials and Abrasive Selection

Material choice directly affects how a flap wheel performs. A Flap Wheel Factory typically works with abrasive grains such as aluminum oxide, zirconia, or ceramic materials. Each grain type behaves differently under pressure and heat, so selection depends on the intended application.

Backing materials also matter. Cloth or fiber backings are chosen based on flexibility and strength requirements. The factory combines these components to create wheels that can handle varying speeds and surface conditions.

Production Process and Assembly

The manufacturing process usually follows a structured flow. Abrasive cloth is cut into flaps, coated with bonding agents, and arranged around a core. In a Flap Wheel Factory, consistency during this stage is critical. Uneven spacing or weak bonding can affect balance and wear behavior.

Once assembled, wheels are cured to strengthen the bond between flaps and the hub. This curing step helps ensure that the flaps remain secure during operation, even under continuous use.

Quality Control and Performance Checks

Quality control is an ongoing process rather than a single inspection. A Flap Wheel Factory may check dimensions, balance, and adhesion strength at different stages of production. Sample wheels are often tested on actual materials to observe wear rate and surface finish.

These checks help maintain stable performance across batches. For users, this means predictable grinding behavior and reduced tool changes during work.

Application-Oriented Design

Flap wheels are used in a wide range of industries, from fabrication shops to shipyards. A Flap Wheel Factory often designs products with specific applications in mind, such as edge grinding, surface blending, or rust removal. Small design choices, like flap angle or grit density, can influence how the wheel behaves on different materials.

By adjusting these details, manufacturers support more precise and efficient surface treatment without changing the basic structure of the product.

Customization for Different Markets

Different regions and industries have different expectations. A Flap Wheel Factory serving international customers may offer variations in size, grit range, or mounting style. Some buyers prefer wheels for handheld tools, while others require versions suited for automated equipment.

Customization allows the same basic product concept to meet diverse working conditions, helping buyers match tools to their processes more accurately.

Long-Term Value for Buyers

Choosing a reliable manufacturer supports consistent supply and communication. Buyers working with an experienced Flap Wheel Factory benefit from stable specifications, clearer technical support, and easier reordering. Over time, this cooperation helps reduce uncertainty in tool performance and inventory planning.

A Flap Wheel Factory plays a steady role in supplying abrasive tools used across many industries. Through careful material selection, controlled assembly, and continuous quality checks, factories produce flap wheels suited for everyday surface finishing tasks. Understanding how these products are made helps buyers select tools that fit real working needs and deliver dependable results in practical applications.

Eng

Eng  عربى

عربى