How Does a Flap Discs Factory Support Daily Metalwork?

2026.01.16

2026.01.16

Industry News

Industry News

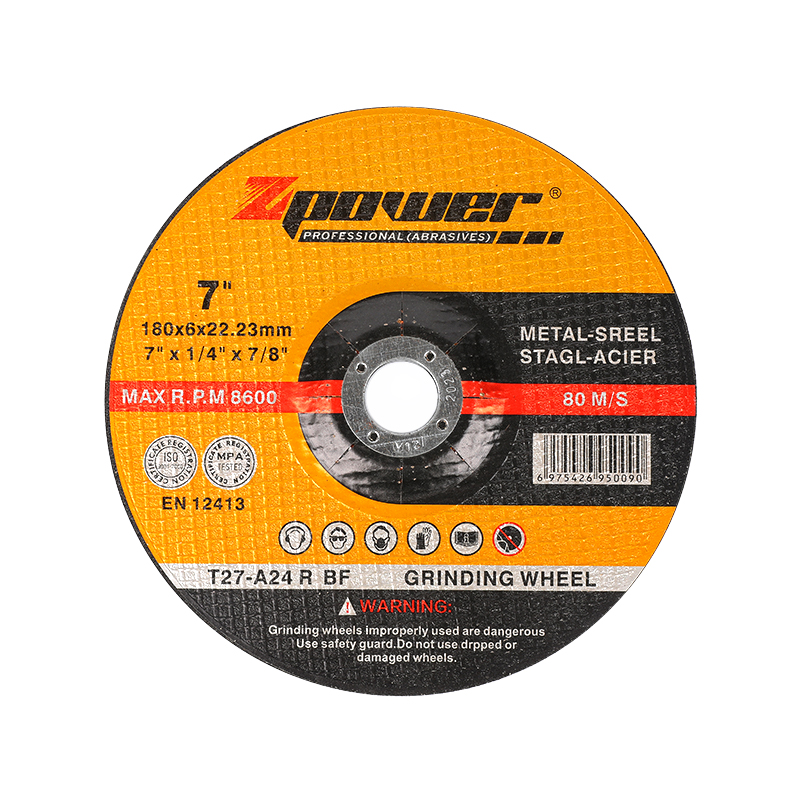

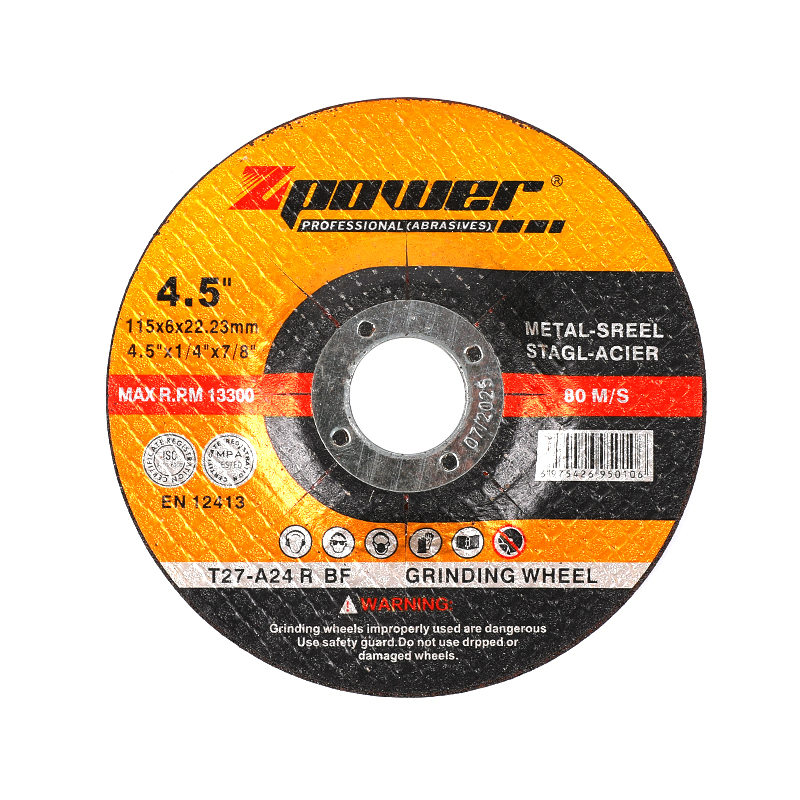

Flap discs are widely used in metal fabrication, construction, and maintenance work. They are valued for their ability to grind, blend, and finish surfaces in a single step. Behind these abrasive tools, a Flap Discs Factory plays an important role in transforming raw materials into products that meet everyday workshop demands.

The Role of a Flap Discs Factory

A Flap Discs Factory is responsible for organizing the entire production process, from material preparation to final inspection. Rather than focusing only on output volume, factories pay attention to disc balance, abrasive consistency, and bonding strength. These factors directly affect how a flap disc performs during grinding or surface finishing.

Factories often work with distributors and industrial users to understand common applications. Feedback from real usage helps guide product adjustments and improves long-term reliability.

Raw Materials and Abrasive Selection

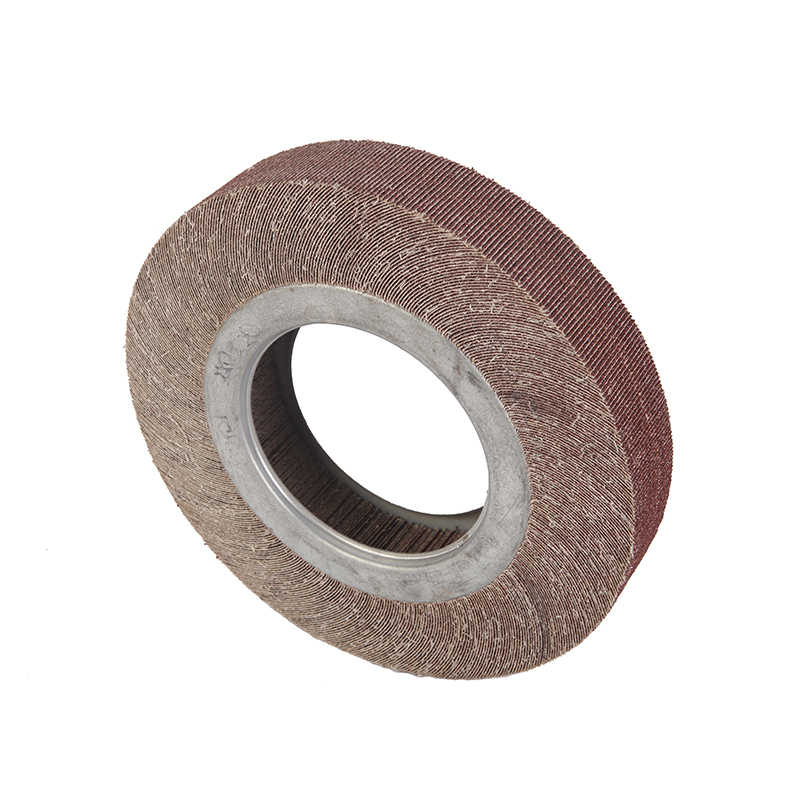

Material choice is one of the most important steps in production. A Flap Discs Factory typically uses coated abrasives such as aluminum oxide, zirconia, or ceramic grains. Each abrasive type behaves differently depending on the surface being worked on and the pressure applied.

Backing materials also matter. Fiberglass or plastic backings provide structural support and help maintain disc stability during rotation. Careful matching of abrasive grain, backing type, and adhesive ensures that the disc wears evenly instead of failing prematurely.

Manufacturing Process and Assembly

Production usually starts with cutting abrasive cloth into uniform flaps. These flaps are arranged in overlapping layers and bonded to the backing plate. The angle, density, and alignment of the flaps influence grinding efficiency and surface finish.

In a Flap Discs Factory, bonding and curing stages are closely controlled. Improper curing can weaken the disc structure, while excessive bonding may reduce flexibility. Maintaining this balance supports steady performance across different working conditions.

Quality Control During Production

Quality control is integrated throughout the manufacturing process. A Flap Discs Factory conducts inspections on abrasive adhesion, flap alignment, and disc balance. Random samples may be tested under rotation to check vibration levels and wear patterns.

Visual inspection also plays a role. Uneven flap spacing or surface defects can affect tool handling. By addressing these issues early, factories reduce waste and ensure consistent batches for shipment.

Adapting to Market and Application Needs

Different industries require different grinding behaviors. Some users focus on rapid material removal, while others prioritize smoother surface blending. To meet these needs, a Flap Discs Factory may adjust grit sizes, flap density, or disc diameter.

Customization options are often available for branding, packaging, or specification changes. These adjustments help distributors serve local markets more effectively without redesigning the entire product line.

Logistics and Ongoing Cooperation

Once products pass inspection, packaging becomes the next focus. Proper packaging helps prevent deformation during transport and keeps abrasive surfaces clean. Clear labeling also supports inventory management and end-user selection.

For long-term cooperation, a Flap Discs Factory often provides technical documentation and usage guidance. Clear communication helps buyers match the right disc to the right task, reducing misuse and unnecessary wear.

A Flap Discs Factory supports metalworking industries by focusing on material selection, structured production, and consistent quality control. Each step, from abrasive choice to final packaging, influences how flap discs perform in real-world applications. For buyers and distributors, understanding these production details helps build confidence in product reliability and long-term cooperation.

Eng

Eng  عربى

عربى