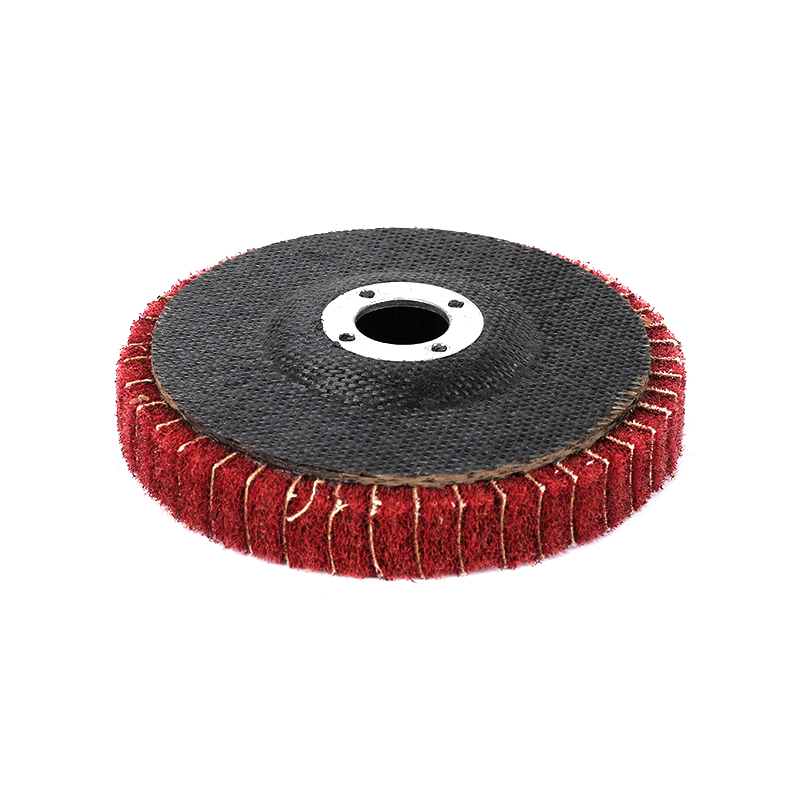

Angle Grinder Flap Grinding Disc

Angle grinder flap grinding discs are versatile tools designed for various grinding and finishing tasks in metalworking, woodworking, and other industries. These discs consist of abrasive flaps bonded radially to a central hub, which allows them to effectively remove material and provide a smooth finish. Here’s a detailed exploration of their features, applications, and advantages:

1. Construction and Design

Angle grinder flap grinding discs are typically constructed with multiple abrasive cloth flaps arranged radially around a central hub. These flaps are made from various abrasive materials such as aluminum oxide, zirconia alumina, or ceramic, depending on the intended application and material hardness. The flaps are angled to provide contact with the workpiece, ensuring efficient material removal and a consistent finish.

2. Key Features

Abrasive Grits: Available in different grit sizes ranging from coarse to fine, allowing for tasks from heavy material removal to fine surface finishing.

Backing Material: Usually made from fiberglass or plastic, providing flexibility and strength to withstand the high rotational speeds of angle grinders.

Diameter and Arbor Size: These come in various diameters (typically 4.5 to 7 inches) and arbor hole sizes to fit different models of angle grinders.

3. Applications

Angle grinder flap grinding discs find applications across several industries and tasks:

Metalworking: Used for grinding welds, removing rust, deburring, and shaping metal surfaces in fabrication and repair work.

Woodworking: Ideal for smoothing wood surfaces, shaping wood edges, and removing old finishes or paint.

Automotive: Effective in automotive body repair for smoothing weld seams and preparing surfaces for painting.

Construction: Used in construction for tasks such as concrete surface preparation and tile adhesive removal.

4. Advantages

Versatility: Can handle a wide range of materials including metals, wood, plastics, and more, making them versatile for various applications.

Aggressive Cutting Action: Due to the abrasive flaps and their arrangement, these discs can remove material quickly and efficiently.

Longevity: Depending on the abrasive material and construction quality, flap discs can last longer than traditional grinding wheels or sanding discs.

Ease of Use: They are easy to install on angle grinders and require less setup time, enhancing productivity.

5. Safety Considerations

While angle grinder flap grinding discs offer significant advantages, safety precautions are crucial:

Eye Protection: Always wear safety glasses or goggles to protect against sparks and debris.

Gloves and Clothing: Wear appropriate gloves and clothing to protect against abrasive particles and heat.

Machine Compatibility: Ensure the flap disc matches the specifications of your angle grinder to prevent accidents.

6. Maintenance and Storage

To prolong the life of angle grinder flap grinding discs:

Proper Storage: Store discs in a dry, cool place to prevent degradation of abrasive materials.

Cleaning: Periodically clean the discs to remove accumulated debris and maintain cutting efficiency.

7. Choosing the Right Disc

Selecting the appropriate flap disc depends on several factors:

Material Type: Consider the material's hardness and the desired finish.

Grit Size: Choose finer grits for smoother finishes and coarser grits for faster material removal.

Disc Diameter: Ensure compatibility with your angle grinder model.

Angle grinder flap grinding discs are indispensable tools in metalworking, woodworking, and construction industries, offering versatility, efficiency, and ease of use. Understanding their construction, applications, and maintenance ensures good performance and safety in various grinding and finishing tasks. Whether for smoothing welds or preparing surfaces, these discs contribute significantly to achieving quality results in industrial and DIY projects alike.

Specifications

|

Material |

Scouring Pad |

|

Diameter |

100mm |

|

Thickness |

16mm |

|

Grit |

120#(Green with sandpaper), 180# (Green), 240#(Red with sandpaper) 320# (Red) |

KEEP IN TOUCH

-

Surface finishing is a key part of metalworking, woodworking, and other fabrication tasks. A Flap Wheel is a versatile tool designed to smooth, deburr, or polish surfaces efficiently. While it may se...

READ MORE -

In metalworking and fabrication, achieving smooth surfaces and precise finishes is essential. Among the tools commonly used for grinding, blending, and polishing, Flap Discs stand out as versatile and...

READ MORE -

Grinding wheels are essential tools in metalworking, construction, and industrial maintenance. Among these, alumina grinding wheels are widely used because of their durability and versatility in cutt...

READ MORE -

Grinding wheels are often treated as routine workshop items, yet their performance depends heavily on how they are made. From cutting stability to wear behavior, many factors are determined long befo...

READ MORE

Eng

Eng  عربى

عربى