What Should You Know About an Alumina Grinding Wheel Factory Before Purchasing?

2026.02.06

2026.02.06

Industry News

Industry News

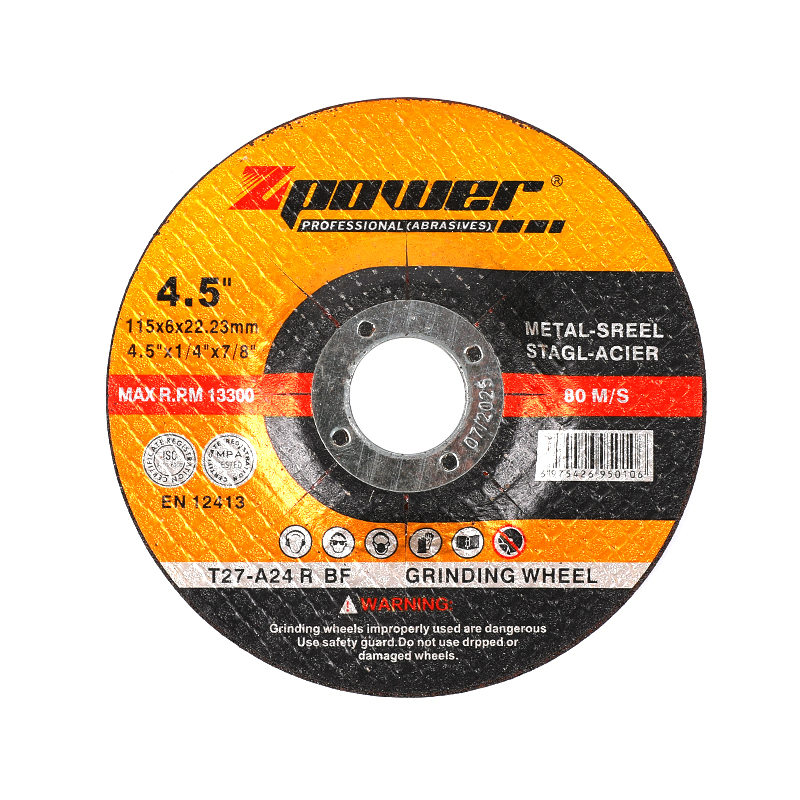

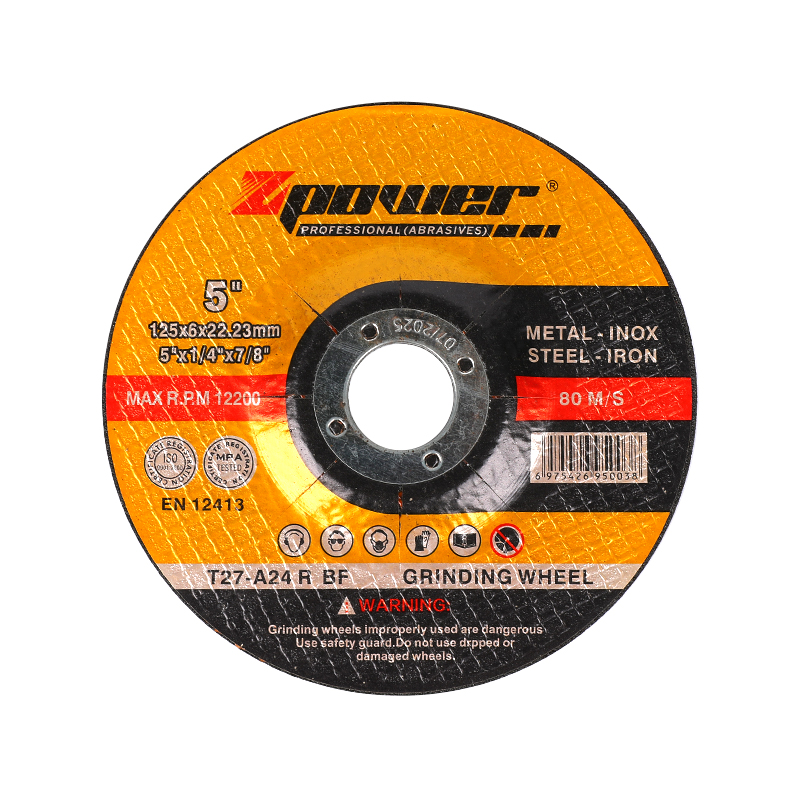

Grinding wheels are essential tools in metalworking, construction, and industrial maintenance. Among these, alumina grinding wheels are widely used because of their durability and versatility in cutting, shaping, and finishing metals. Understanding the role of an Alumina Grinding Wheel Factory can provide valuable insight into production processes, quality control, and product selection, which is especially useful for distributors, workshop managers, and buyers.

Production Process Overview

An Alumina Grinding Wheel Factory transforms raw materials such as aluminum oxide and bonding agents into durable and precise grinding tools. The process begins with careful mixing of abrasives and binders, followed by pressing or molding the mixture into the desired wheel shape. After forming, the wheels are sintered at controlled temperatures to achieve proper hardness and structural integrity. Each step requires accuracy to maintain uniform density, balance, and performance. In some factories, advanced molding techniques are employed to reduce porosity and improve longevity.

Quality Control Measures

Quality control is a central focus of any Alumina Grinding Wheel Factory. Wheels are inspected for shape accuracy, hardness, grain distribution, and structural integrity. Dynamic balance tests may be conducted to reduce vibration during high-speed rotation. Consistent quality ensures that wheels perform predictably and reduce the risk of damage to workpieces or machinery. Detailed records of testing procedures, batch tracking, and traceability are also features that buyers often look for when evaluating a factory.

Customization and Product Range

Customization is another area where an Alumina Grinding Wheel Factory adds value. Factories may offer various diameters, thicknesses, abrasive grades, and bonding types to suit cutting, grinding, or finishing needs. Specialized industries such as automotive, aerospace, or tool manufacturing often require custom wheels. Understanding the factory's ability to adjust size, hardness, and abrasive type allows buyers to select tools that meet their exact project requirements. Some factories even provide consultation on selecting the appropriate wheel for specific materials or machinery.

Safety and Handling Considerations

Safety is a primary concern when using grinding wheels. Tools must be free from cracks, defects, or imbalances that could lead to failure during high-speed rotation. A reliable Alumina Grinding Wheel Factory enforces strict inspection standards and provides guidance on safe usage, storage, and mounting procedures. Factories that include clear instructions, proper packaging, and compliance with industry safety standards make it easier for buyers to implement correct handling practices in their workplaces.

Efficiency and Production Capability

The production capacity of an Alumina Grinding Wheel Factory is crucial for delivery timelines, especially for bulk orders. Factories with organized workflow, automated presses, and controlled sintering processes can maintain consistent output without sacrificing quality. Communicating order volumes, deadlines, and project specifications with the factory helps buyers plan procurement schedules and avoid unexpected delays. Efficient factories can also respond to urgent orders or adjust production sequences when necessary.

After-Sales Support

Support beyond delivery is another important consideration. Many factories provide advice on wheel selection, maintenance, and troubleshooting, which can prevent operational issues and extend the lifespan of the tools. A responsive Alumina Grinding Wheel Factory ensures smoother cooperation and helps buyers address concerns during usage. Guidance on proper storage, inspection routines, and replacement schedules adds practical value to long-term operations.

An Alumina Grinding Wheel Factory plays a critical role in producing reliable, consistent, and safe grinding tools. By understanding production methods, quality control practices, customization options, and safety standards, buyers can make informed decisions when sourcing wheels. Engaging with a knowledgeable factory not only ensures product quality but also supports long-term operational efficiency, safety, and adaptability in various industrial applications. With careful selection and collaboration, these factories provide the tools necessary to maintain smooth and productive workflows.

Eng

Eng  عربى

عربى