How Does a Flap Wheel Improve Surface Finishing?

2026.02.20

2026.02.20

Industry News

Industry News

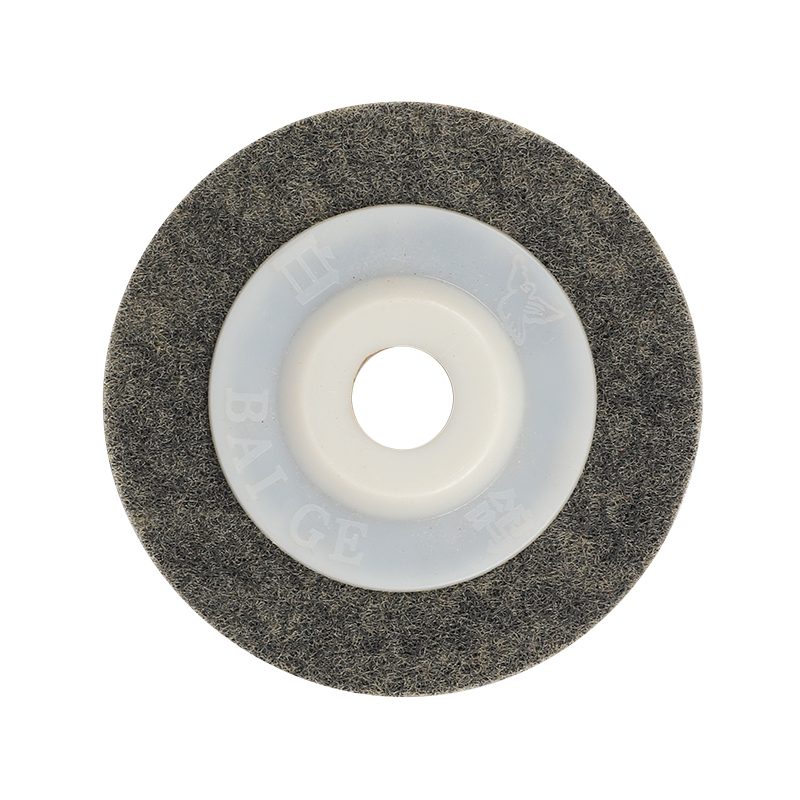

Surface finishing is a key part of metalworking, woodworking, and other fabrication tasks. A Flap Wheel is a versatile tool designed to smooth, deburr, or polish surfaces efficiently. While it may seem like a simple abrasive wheel, its design allows controlled material removal, even on irregular or curved surfaces.

What Is a Flap Wheel?

A Flap Wheel consists of multiple overlapping abrasive flaps attached around a central hub. The flaps flex and conform to the surface being worked on, which allows consistent contact without creating deep grooves. Unlike standard sanding discs, the flexibility of the flaps makes it easier to work on rounded edges, corners, or contours.

The abrasive material on each flap can vary depending on the intended use, ranging from coarse grit for heavy material removal to fine grit for polishing or finishing.

Common Applications

Flap wheels are widely used across industries and workshops. In metalworking, they remove rust, paint, or oxidation from sheet metal, pipes, and castings. Woodworkers use them to smooth edges or remove imperfections from carvings and furniture components. Even in plastic or composite fabrication, flap wheels can gently refine surfaces without damaging the material.

Because of their adaptability, a Flap Wheel can be mounted on various power tools, including drills, die grinders, or dedicated bench grinders. This versatility allows users to adjust speed and pressure based on the material and desired finish.

Choosing the Right Flap Wheel

Selecting a Flap Wheel depends on grit, flap material, wheel diameter, and the type of hub. Coarse grits are useful for heavy stock removal, while medium or fine grits are better for finishing tasks. Abrasive flaps can be made of aluminum oxide, zirconia, or ceramic materials, each offering different wear resistance and cutting properties.

The correct choice ensures consistent results and extends the life of both the wheel and the workpiece.

Technique and Safety Tips

Using a Flap Wheel effectively requires attention to technique and safety. Light to moderate pressure allows the flaps to work as intended without overloading the wheel. Maintaining a consistent motion helps avoid uneven finishes or gouging. Protective gear, such as safety goggles and gloves, is recommended when working with metal or other debris-prone materials.

Because flap wheels spin at high speeds, secure attachment to the tool and proper machine operation are essential to prevent accidents.

Maintenance and Longevity

While flap wheels wear naturally with use, proper storage and usage can extend their life. Keeping wheels dry and free from oil or dust buildup prevents deterioration of the abrasive material. Rotating between different grit levels can also reduce the need for frequent replacements.

Regular inspection for damaged or frayed flaps helps maintain safety and performance during operation.

Versatility and Value

A Flap Wheel offers a practical solution for finishing tasks that require flexibility, precision, and adaptability. Its ability to handle flat, curved, or irregular surfaces makes it suitable for workshops, industrial fabrication, and hobby projects alike. By providing consistent results and reducing manual effort, it becomes a reliable tool for both professionals and DIY enthusiasts.

Eng

Eng  عربى

عربى