What Industries Rely on Grinding Wheels Manufacturer Products?

2025.10.03

2025.10.03

Industry News

Industry News

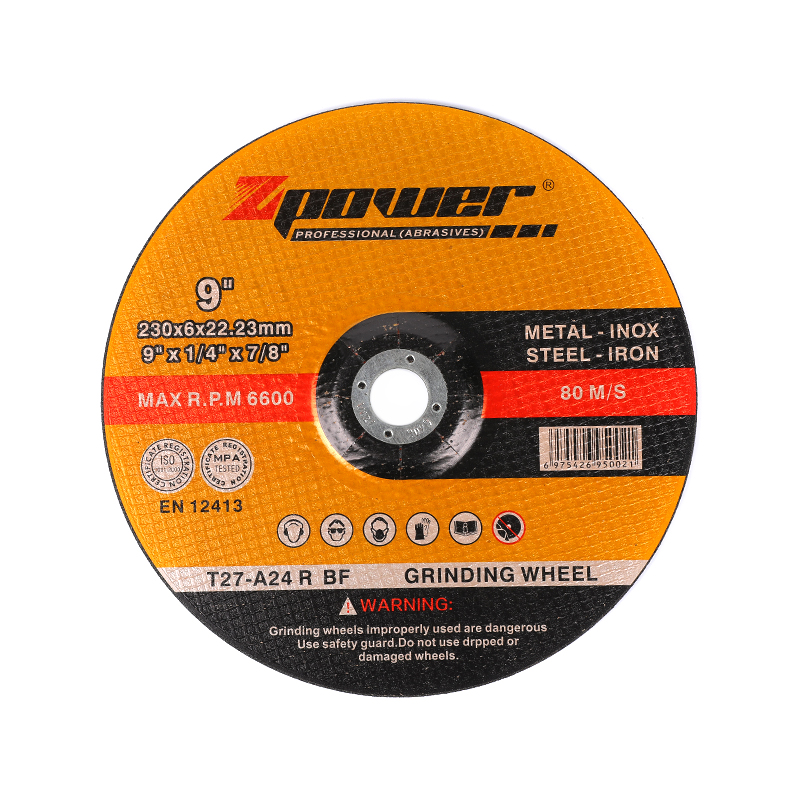

Grinding wheels are essential tools in various industries, providing the necessary abrasive surface to grind, cut, and shape materials. These products are widely used for their precision and ability to handle different materials, from metals to ceramics. Grinding wheels manufacturer products are integral to multiple sectors, each relying on these tools to achieve high-quality results and maintain efficient production processes.

1. Metalworking Industry

The metalworking industry is perhaps the largest consumer of grinding wheels. Manufacturers in this sector use grinding wheels for a variety of tasks, including cutting, grinding, polishing, and shaping metals. These wheels are used to sharpen tools, refine metal surfaces, and even prepare metals for welding. Grinding wheels help to create the precise edges and smooth finishes required in industries like automotive manufacturing, aerospace, and general metal fabrication.

For example, grinding wheels are essential in automotive production lines, where they are used to shape engine components, brake parts, and other metal pieces. Precision grinding is crucial in ensuring that parts fit together properly, meet safety standards, and perform reliably.

2. Tool and Die Making

Tool and die making is another industry that heavily relies on the products of grinding wheels manufacturers. These industries produce tools, molds, and dies used in manufacturing processes for various products. The grinding wheels used here are typically designed for fine precision, helping to sharpen and finish high-tolerance tools.

In this sector, grinding wheels are used to shape the hard materials often found in tools and dies, such as high-speed steel and carbide. Without reliable grinding wheels, producing accurate and durable tools for industries like metal stamping or injection molding would be much more difficult.

3. Electronics and Semiconductor Industry

The electronics and semiconductor industry uses grinding wheels in the production and assembly of components such as circuit boards and semiconductor devices. Grinding wheels are necessary to create the fine, precise cuts and surfaces required in the tiny, delicate parts used in electronics.

Grinding wheels are used to polish wafers and substrates, smooth out rough edges, and refine features on semiconductor devices. These operations demand extremely high precision, and grinding wheels must meet strict quality standards to ensure that components function correctly in highly sensitive electronic applications.

4. Construction and Engineering

In the construction and engineering sectors, grinding wheels play a key role in cutting and shaping construction materials, such as concrete, stone, and masonry. These industries use grinding wheels to smooth surfaces, remove excess material, and prepare surfaces for further treatment, such as sealing or painting.

Diamond grinding wheels, for instance, are often used to cut through tough materials like concrete and stone. Their abrasive properties allow workers to perform tasks such as surface finishing, cutting tiles, and reshaping stone and concrete surfaces efficiently and accurately.

5. Woodworking Industry

Though primarily associated with metal and stone processing, grinding wheels are also used in the woodworking industry. Grinding wheels are essential in shaping and sharpening tools such as saw blades, chisels, and routers. Woodworkers rely on the durability and precision of these wheels to maintain the sharpness and functionality of their tools, ensuring they can work efficiently and safely.

Grinding wheels manufactured for different industries are vital to various processes, from metalworking and tool making to electronics and woodworking. These products allow industries to achieve precise cuts, smooth finishes, and sharpen tools, making them essential in the production of high-quality goods. By relying on grinding wheels manufacturer products, businesses can maintain efficiency, precision, and safety across a range of demanding tasks.

Eng

Eng  عربى

عربى