How Do Manufacturers Innovate Flap Wheel Designs?

2025.09.26

2025.09.26

Industry News

Industry News

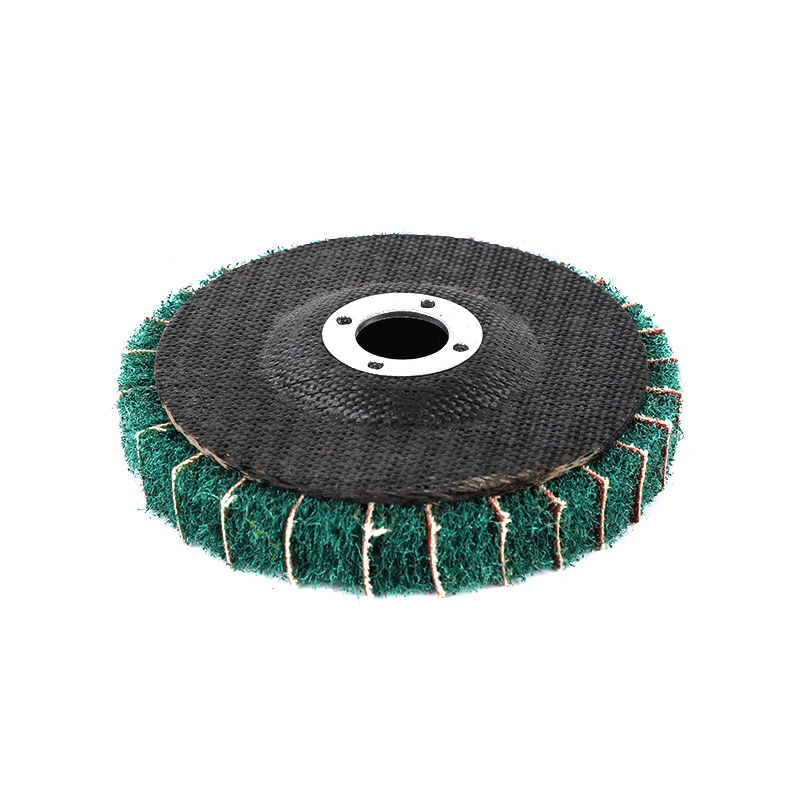

Flap wheels are essential tools used in industries such as metalworking, woodworking, and automotive manufacturing. These versatile abrasive tools are designed to provide smooth finishes, remove rust, or polish surfaces. Flap wheel manufacturers constantly innovate their designs to improve performance, durability, and efficiency.

1. Enhanced Abrasive Materials

One of the main ways flap wheel manufacturers innovate is by experimenting with different abrasive materials. Traditional flap wheels used aluminum oxide or silicon carbide, but advancements in materials science have introduced more specialized options. Manufacturers are now utilizing ceramics, zirconia alumina, and other advanced abrasives that offer higher cutting efficiency and longer lifespan.

These new materials help manufacturers create flap wheels that can handle more demanding tasks, such as grinding harder metals or polishing more intricate surfaces. By improving the quality of the abrasives used, manufacturers can provide tools that perform better and last longer, reducing downtime for industries that rely on flap wheels for continuous operations.

2. Customization and Variety in Grit Sizes

Flap wheel manufacturers also innovate by offering a wider range of grit sizes and designs to suit various applications. Different industries require different levels of abrasiveness, and a one-size-fits-all approach doesn't always work. Manufacturers now produce flap wheels with finer grits for polishing and smoothing delicate surfaces, as well as coarser grits for heavy-duty grinding tasks.

By providing more customizable options, manufacturers allow customers to choose flap wheels that best meet their specific needs. This customization helps improve the precision and efficiency of the tasks at hand, ensuring that users can select the perfect flap wheel for their particular project.

3. Improved Design and Construction

Flap wheel design has also seen considerable innovation. Manufacturers now use advanced techniques to optimize the construction of flap wheels. For example, the number of abrasive flaps, their arrangement, and the materials used to attach them have all been refined to improve performance. Some modern flap wheels feature a higher number of overlapping flaps that provide more surface contact, resulting in smoother finishes and greater durability.

In addition, manufacturers are creating flap wheels with better attachment systems, such as reinforced hubs or quick-change features, to increase ease of use and reduce downtime during operations. These design enhancements not only make the flap wheels more effective but also easier and safer to work with.

4. Specialized Designs for Specific Applications

Flap wheel manufacturers are increasingly focused on creating specialized designs for specific applications. For example, some flap wheels are designed for use on specific types of materials, such as stainless steel, aluminum, or wood. Manufacturers are also producing flap wheels that can work in tight spaces, making them suitable for intricate tasks like polishing curved surfaces or edges.

This level of specialization ensures that industries can access the right tools for their unique challenges, improving productivity and the quality of the finished product.

5. Environmental Considerations

As environmental concerns continue to grow, flap wheel manufacturers are also looking at ways to make their products more eco-friendly. Some manufacturers are using recyclable materials for the construction of the flap wheels, reducing waste and environmental impact. Additionally, advancements in abrasive technology have led to the creation of more efficient products, reducing the need for excessive abrasive material and improving the overall sustainability of the industry.

Flap wheel manufacturers continue to innovate by enhancing abrasive materials, offering more customization, refining designs, and addressing environmental concerns. These innovations not only improve the performance and durability of flap wheels but also help industries work more efficiently and effectively. As the demands of the manufacturing world evolve, flap wheel manufacturers will undoubtedly continue to find new ways to meet these challenges with cutting-edge designs.

Eng

Eng  عربى

عربى