Can Grinding Wheels Manufacturers Customize Wheels for Specific Applications?

2025.10.10

2025.10.10

Industry News

Industry News

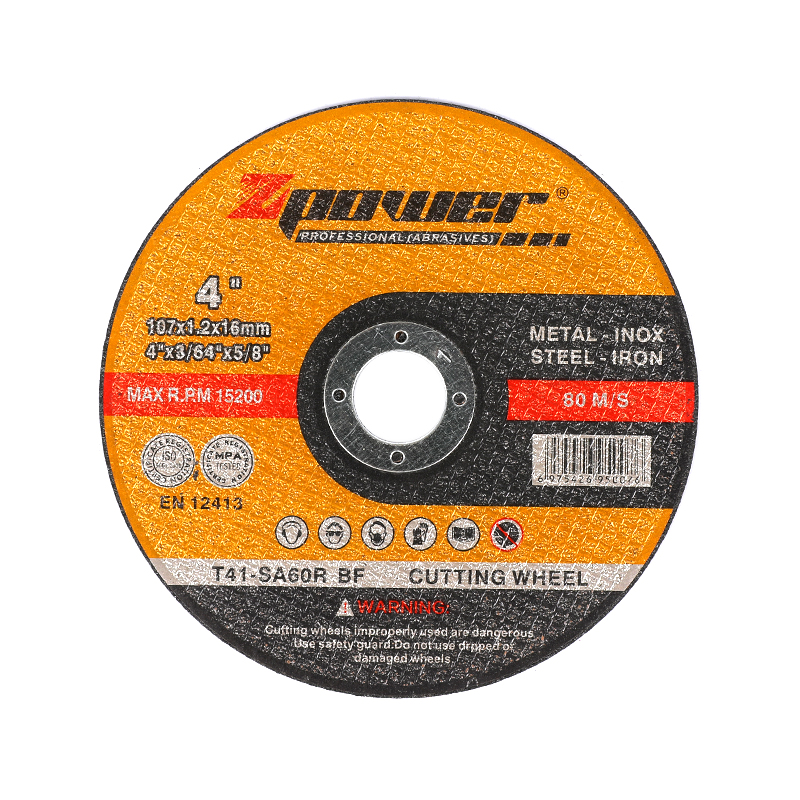

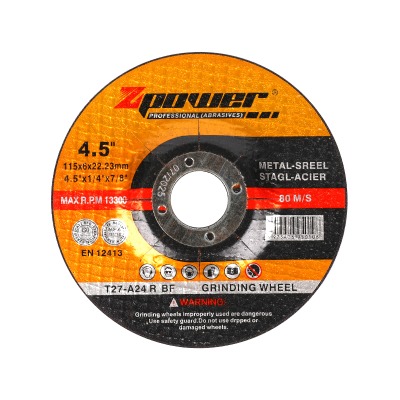

Grinding wheels are essential tools in metalworking, construction, and manufacturing, providing precise material removal and surface finishing. Different applications require varying wheel properties, such as grit size, bond type, hardness, and shape. This raises the question: can grinding wheels manufacturers customize wheels for specific needs?

Understanding Application Requirements

The first step in customization is understanding the intended application. Grinding wheels are used for cutting, shaping, or finishing materials like metal, stone, ceramics, and composites. Each material type demands specific wheel characteristics. For example, harder metals often require wheels with a softer bond to prevent glazing, while softer metals may benefit from harder wheels to maintain shape during cutting. Grinding wheels manufacturers typically work closely with clients to assess material type, surface finish expectations, and production speed requirements before recommending a customized solution.

Material Selection and Grit Options

Custom grinding wheels are designed by selecting appropriate abrasive materials and grit sizes. Common abrasives include aluminum oxide, silicon carbide, cubic boron nitride, and diamond, each suited for particular materials. Manufacturers can adjust grit size to influence cutting speed, surface finish, and wheel life. Fine grits offer smooth finishes, while coarse grits allow for rapid material removal. By combining specific abrasive types and grit sizes, grinding wheels manufacturers create wheels tailored to the client's precise application needs.

Bond Types and Wheel Hardness

The bond and hardness of a grinding wheel significantly affect its performance. Bonds, which hold abrasive grains together, can be vitrified, resin, rubber, or metal, depending on the desired strength and flexibility. Hardness determines how firmly the grains are held, influencing wear rate and cutting efficiency. Grinding wheels manufacturers customize both bond type and hardness to match the working material and operational conditions. This ensures consistent performance, reduces wheel wear, and improves the quality of the finished surface.

Shape and Dimension Customization

Different applications require specific wheel shapes and dimensions. Manufacturers can produce grinding wheels in various profiles, such as straight, tapered, cup-shaped, or mounted wheels. The wheel diameter, thickness, and bore size can also be adjusted to fit particular machines or operational setups. This flexibility allows workshops to maintain precision and efficiency while accommodating unique equipment requirements or unusual workpiece geometries.

Quality Assurance and Testing

Custom grinding wheels undergo strict quality control before reaching clients. Manufacturers perform tests to measure balance, concentricity, hardness, and cutting performance. These tests ensure that the wheel meets specifications and delivers reliable results in practical applications. By adhering to quality standards, grinding wheels manufacturers provide customized solutions that are safe, durable, and efficient for industrial use.

Grinding wheels manufacturers can indeed customize wheels for specific applications by adjusting abrasive material, grit size, bond type, hardness, shape, and dimensions. This customization allows businesses to optimize performance for different materials, improve efficiency, and achieve desired surface finishes. Collaborating closely with a manufacturer ensures that the grinding wheels are tailored to operational requirements, offering reliable, application-specific solutions for a wide range of industries.

Eng

Eng  عربى

عربى