What Features Make Alumina Grinding Wheels Reliable?

2025.10.17

2025.10.17

Industry News

Industry News

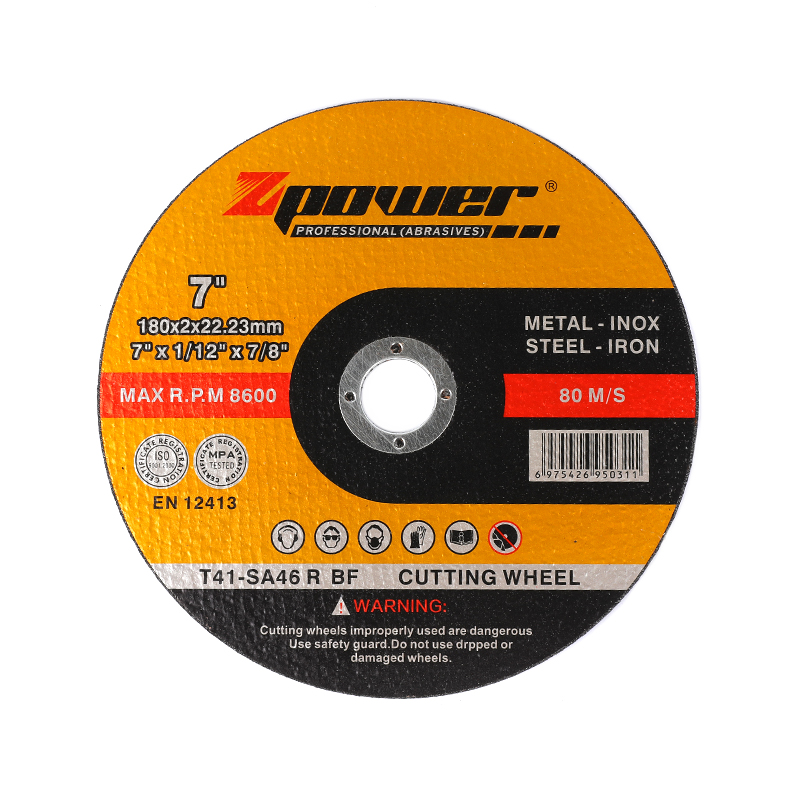

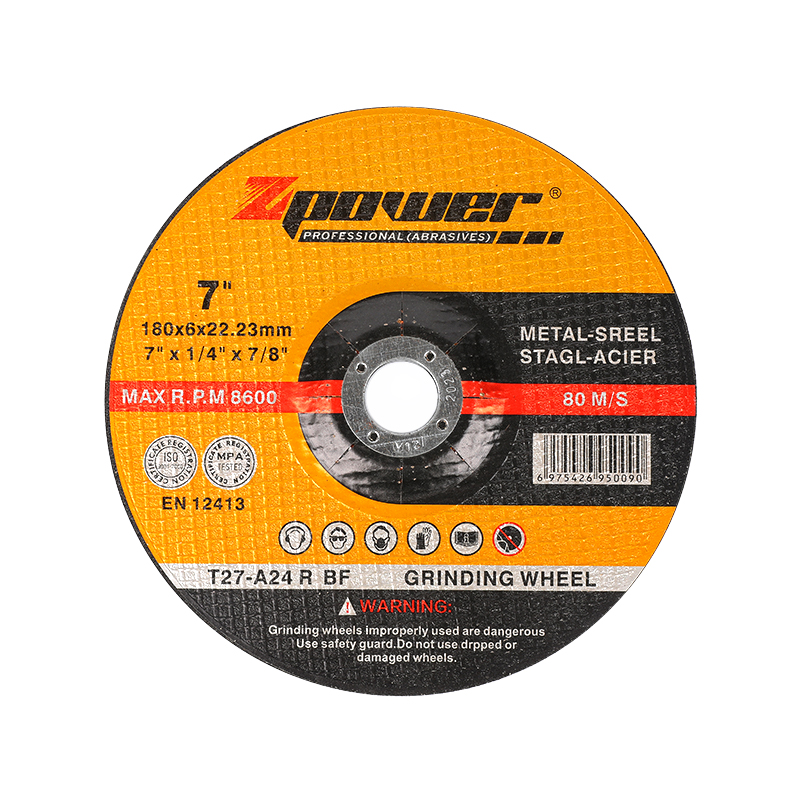

Alumina grinding wheels are essential tools in metalworking, construction, and manufacturing. Their ability to efficiently remove material while maintaining durability is crucial for productivity and safety. An Alumina Grinding Wheel Factory produces these wheels with specific qualities to ensure reliability and consistent performance.

Material Quality and Composition

A reliable grinding wheel starts with the quality of its raw materials. Alumina, or aluminum oxide, is widely used because of its hardness and wear resistance. A reputable Alumina Grinding Wheel Factory carefully selects alumina grains with consistent size and purity. Uniform grain size ensures smooth cutting, while high-purity alumina reduces the risk of impurities causing cracks or uneven wear.

The bonding material, which holds the grains together, is equally important. Strong bonds maintain the wheel's shape under pressure and heat, preventing premature breakage. The combination of high-quality alumina and effective bonding ensures a wheel that performs consistently even under demanding conditions.

Balanced Structure and Design

The structural integrity of a grinding wheel greatly influences its reliability. Properly manufactured wheels have a balanced design, which minimizes vibration during use. Excessive vibration can lead to uneven grinding, decreased precision, and potential safety hazards.

An Alumina Grinding Wheel Factory often employs strict quality control measures, such as dynamic balancing and dimensional inspections, to ensure that each wheel maintains its intended shape and weight distribution. These measures help operators achieve smoother, more precise results while reducing wear on both the tool and the machine.

Heat Resistance and Durability

Grinding generates friction and heat, which can affect the wheel's performance. Reliable alumina grinding wheels are designed to withstand high temperatures without degrading. Certain types of alumina and bond combinations are selected to maintain hardness even when the wheel becomes hot.

Durability is another key feature. A well-made wheel resists crumbling, glazing, or excessive wear over time. This longevity reduces downtime, lowers replacement costs, and ensures consistent cutting efficiency.

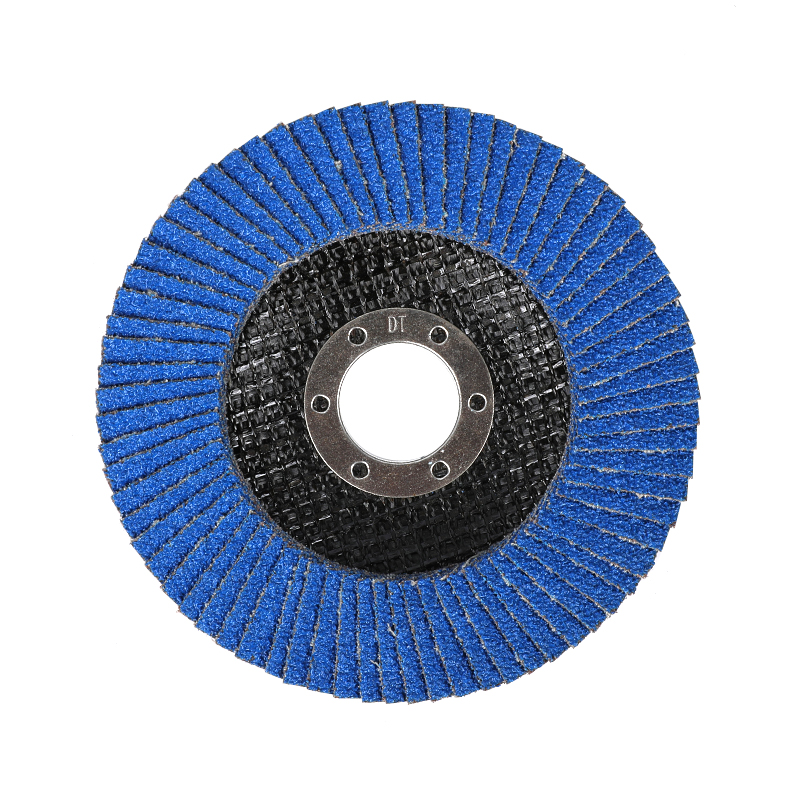

Versatility and Application-Specific Design

Different grinding tasks require wheels with varying hardness, grit sizes, and bonding types. A reputable Alumina Grinding Wheel Factory produces a range of options tailored to specific materials and applications, from soft metals to hardened steel. This versatility allows users to select a wheel that delivers reliable results for the task at hand.

Additionally, some wheels are designed for wet or dry grinding, with features that minimize dust and debris, further improving reliability and safety in the workplace.

Quality Control and Testing

Reliability also comes from strict testing standards. A trustworthy alumina grinding wheel undergoes inspections for balance, hardness, grain distribution, and bonding strength before reaching the market. Factories may perform trial runs or stress tests to simulate real-world conditions, ensuring that each wheel meets performance and safety expectations.

The reliability of alumina grinding wheels depends on high-quality materials, balanced design, heat resistance, application-specific versatility, and rigorous quality control. An Alumina Grinding Wheel Factory focuses on these features to provide wheels that perform consistently and safely. Whether for metal fabrication, construction, or precision engineering, selecting a well-made alumina grinding wheel ensures effective material removal, long-lasting performance, and a safer working experience.

Eng

Eng  عربى

عربى