What Factors Affect Flap Wheel Performance and Longevity?

2025.10.24

2025.10.24

Industry News

Industry News

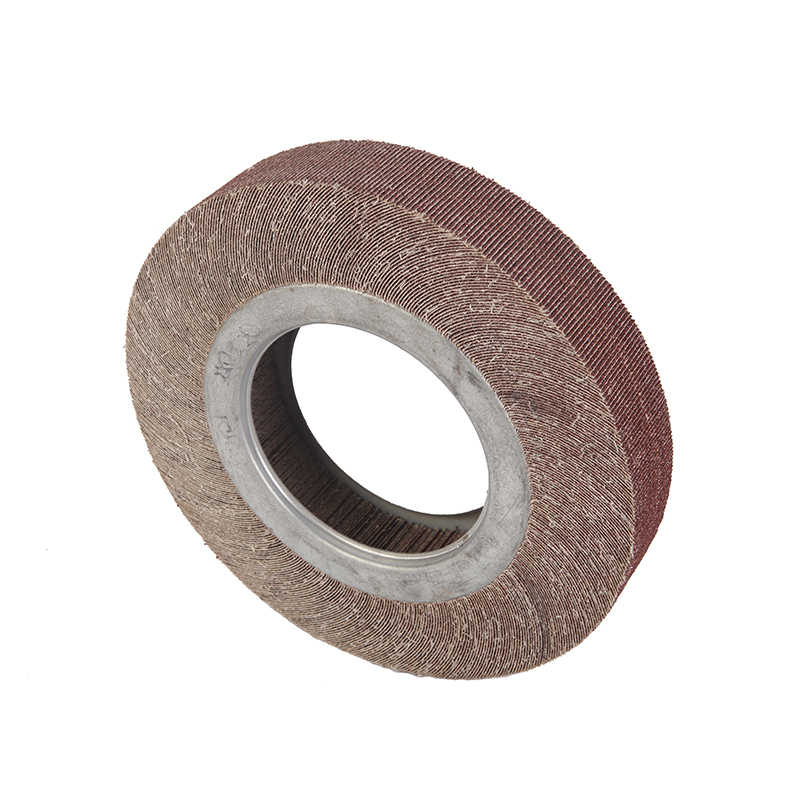

Flap wheels are widely used in metalworking, woodworking, and finishing tasks due to their ability to smooth surfaces, remove rust, and polish materials. However, not all flap wheels perform equally, and their lifespan can vary significantly depending on several factors. Understanding what affects flap wheel performance and longevity can help users select the right product and use it effectively. A reliable flap wheel manufacturer often considers these factors during production to ensure consistent quality.

Material of the Abrasive Flaps

The abrasive material of the flaps is one of the main factors influencing performance. Flap wheels can be made from aluminum oxide, zirconia alumina, or ceramic grains. Each material has unique properties: aluminum oxide is versatile and suitable for general-purpose use, zirconia alumina is durable and ideal for heavy-duty grinding, while ceramic grains offer high wear resistance. Choosing the correct abrasive material based on the application ensures efficient material removal and extends the wheel's lifespan.

Backing Material and Construction

The backing material and how the flap wheel is constructed also affect its durability. Flaps are typically attached to a central hub or core, which can be made of plastic, metal, or fiber. A sturdy backing prevents wobbling and uneven wear during use. High-quality flap wheels have well-secured flaps arranged to distribute pressure evenly. This design minimizes flap tearing, maintains consistent contact with the workpiece, and helps the wheel last longer.

Wheel Size and Grit Selection

The size of the flap wheel and the grit of the abrasive influence both performance and longevity. Larger wheels can cover more surface area but may require more power to operate effectively. Finer grits provide smoother finishes but wear out faster under heavy use, while coarser grits remove material more quickly and tend to last longer in rough applications. Matching the wheel size and grit to the task is essential for maintaining efficiency and extending the wheel's service life.

Operating Speed and Technique

How the flap wheel is used has a direct impact on its lifespan. Operating at excessive speeds can generate heat, leading to premature wear or damage. Applying too much pressure can also cause flaps to fray or break. Manufacturers often provide recommended speed ranges and usage instructions to help users avoid common mistakes. Proper technique, such as steady, controlled movements and maintaining consistent contact with the surface, ensures even wear and prolongs the wheel's effectiveness.

Storage and Environmental Conditions

Flap wheels are sensitive to storage and environmental conditions. Exposure to moisture can weaken the adhesive that holds the flaps, while extreme temperatures can make the material brittle or less flexible. Storing flap wheels in a dry, temperature-controlled environment helps preserve their integrity. A reputable flap wheel manufacturer may include guidance on storage conditions to prevent early degradation.

Regular Inspection and Maintenance

Regular inspection is important for ensuring consistent performance. Users should check for worn, torn, or loose flaps and replace wheels when necessary. Monitoring the condition of the wheel prevents damage to workpieces and ensures that grinding or polishing remains efficient. Routine maintenance, such as cleaning the flaps to remove debris, can also help maintain performance and extend the wheel's usable life.

Flap wheel performance and longevity are influenced by abrasive material, backing construction, wheel size and grit, operating speed, storage conditions, and maintenance practices. Choosing the right flap wheel and following proper usage and storage guidelines can significantly improve efficiency and lifespan. Working with a trusted flap wheel manufacturer ensures that these factors are carefully considered during production, providing reliable and durable products for various applications.

Eng

Eng  عربى

عربى