How Do Grinding Wheels Manufacturers Innovate Their Products?

2025.10.27

2025.10.27

Industry News

Industry News

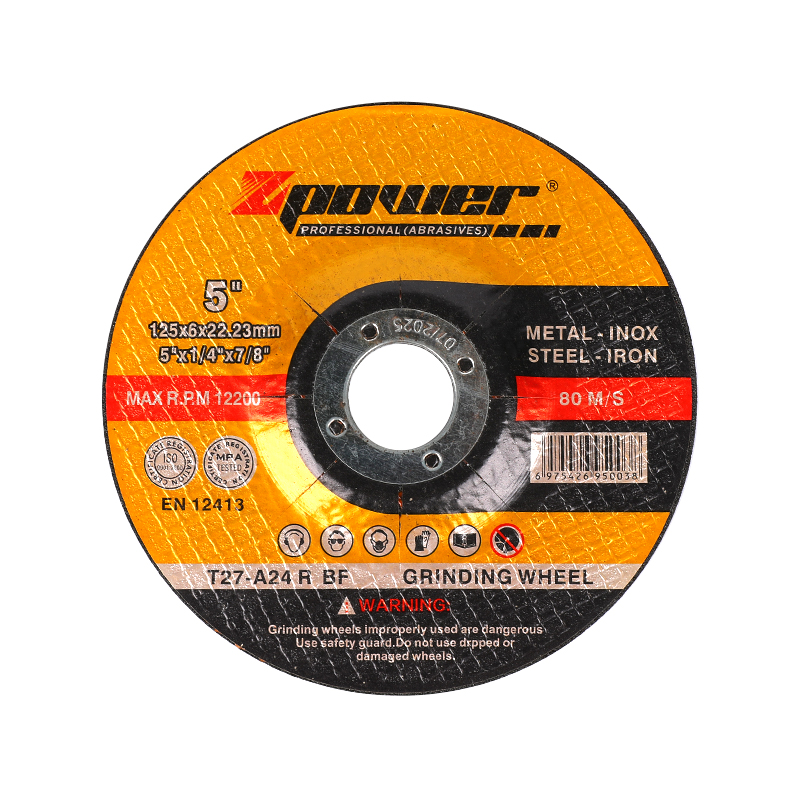

Grinding wheels are essential tools in metalworking, woodworking, and various industrial applications. To keep up with evolving production demands, grinding wheels manufacturers continuously explore ways to enhance their products. Innovation in grinding wheels often focuses on improving efficiency, durability, and adaptability to different materials. Understanding how manufacturers approach innovation provides insight into the evolution of these vital tools.

Material Advancements

One of the primary areas of innovation is the materials used in grinding wheels. Manufacturers experiment with different abrasives, such as aluminum oxide, silicon carbide, and ceramic grains, to meet specific cutting and grinding requirements. These materials are selected based on hardness, toughness, and thermal resistance.

By adjusting the composition of abrasives and bonding agents, grinding wheels manufacturers can produce wheels that last longer, maintain sharper edges, and generate less heat during operation. This helps reduce wear on the workpiece and improves overall efficiency.

Design and Structure Improvements

Innovative design is another way manufacturers enhance grinding wheels. The structure of the wheel, including its density, porosity, and grain orientation, directly affects performance. For example, some wheels are designed with open structures to allow better coolant flow and chip removal, reducing friction and heat buildup.

Manufacturers also explore various shapes and profiles to suit specific applications. Wheels with tapered, cup, or straight designs can target precision tasks, heavy material removal, or specialized finishes. These design improvements help users achieve consistent results across different projects.

Integration of Technology

Technology integration plays an increasing role in grinding wheel innovation. Some manufacturers incorporate sensors or smart systems that monitor wear, temperature, and vibration during use. This data can guide maintenance schedules, prevent damage to machinery, and optimize grinding processes.

Additionally, advancements in computer-aided design (CAD) and simulation software allow manufacturers to predict wheel performance before production. This reduces trial-and-error testing and accelerates the development of wheels tailored for specific tasks or materials.

Environmental and Safety Considerations

Grinding wheels manufacturers are also innovating with sustainability and safety in mind. Developing wheels that produce less dust, noise, and heat benefits both operators and the environment. Some manufacturers are experimenting with eco-friendly bonding agents and materials that are easier to recycle.

Safety enhancements, such as improved balancing, reinforced cores, and protective coatings, are incorporated to minimize the risk of accidents during high-speed operation. These innovations demonstrate a growing emphasis on user well-being alongside performance.

Collaborative Innovation

Many grinding wheels manufacturers collaborate with end-users, research institutions, and industry partners to drive innovation. Feedback from workshops, factories, and professionals helps manufacturers understand real-world challenges and refine their designs accordingly.

Such collaborations can result in customized solutions for specific industrial applications, enabling companies to achieve higher efficiency and precision without compromising safety or durability.

Grinding wheels manufacturers innovate by advancing materials, refining design, integrating technology, and prioritizing safety and sustainability. Through continuous research and collaboration, they adapt to evolving industrial needs, offering products that enhance performance and meet the expectations of diverse users.

Eng

Eng  عربى

عربى