How to Maintain and Store Angle Grinder Grinding Wheels for Longevity

2025.08.15

2025.08.15

Industry News

Industry News

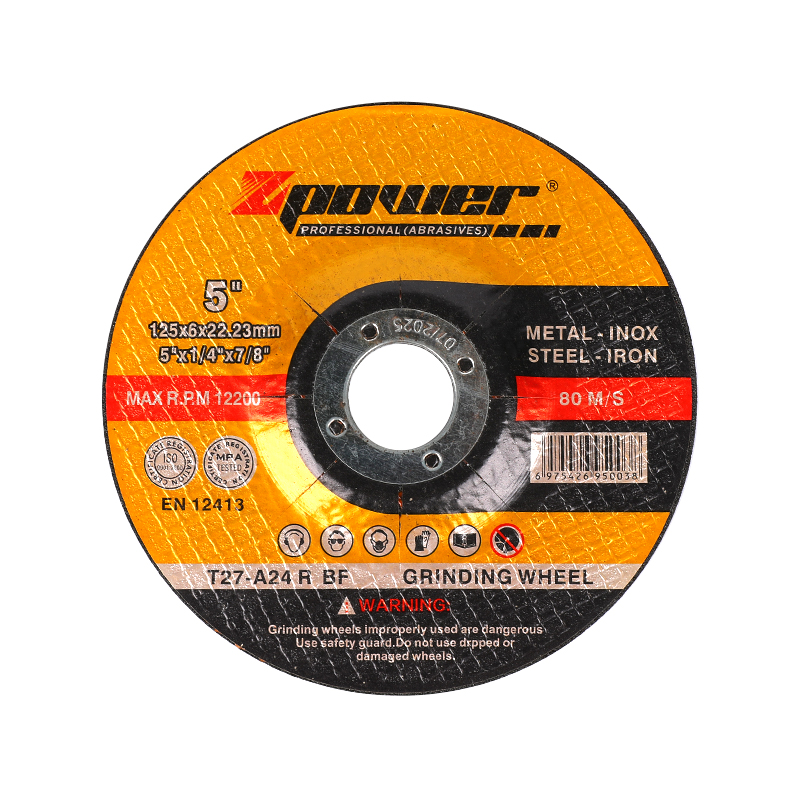

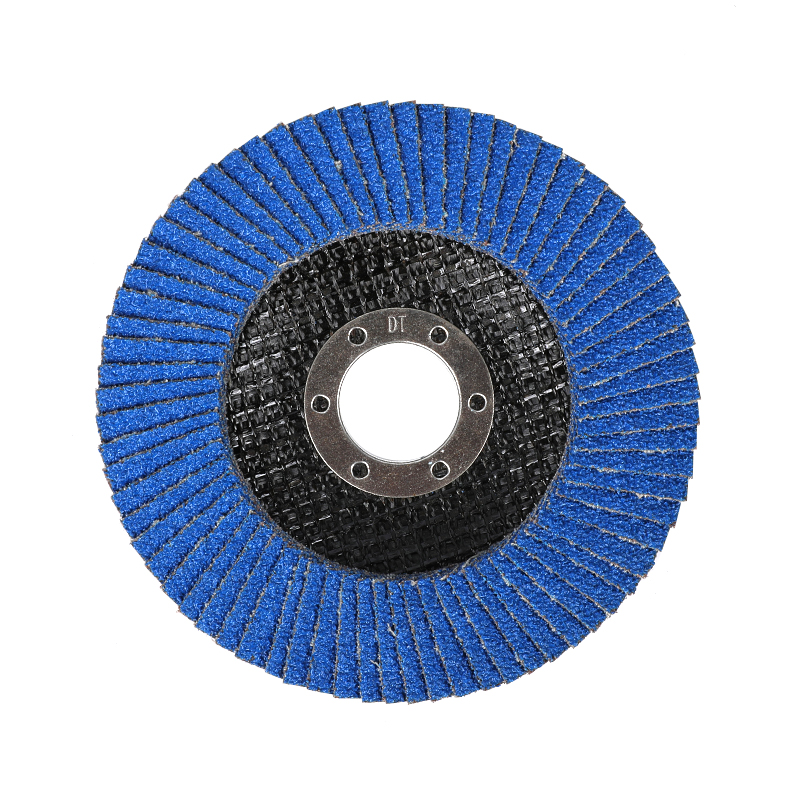

Angle grinder grinding wheels are essential components for cutting, grinding, and shaping various materials in construction, metalworking, and DIY projects. Proper maintenance and storage of these wheels are crucial for ensuring their performance and safety over time. By taking care of your angle grinder grinding wheels, you can extend their lifespan, maintain consistent results, and reduce the risk of accidents during use.

One important aspect of maintaining angle grinder grinding wheels is regular inspection. Before each use, it’s advisable to check the wheel for any visible signs of damage, such as cracks, chips, or uneven wear. Using a damaged grinding wheel can be dangerous, as it may shatter during operation. Inspecting the wheel carefully ensures that you identify any issues early and replace the wheel when necessary. This simple step contributes significantly to the safety of both the operator and the equipment.

Cleaning the grinding wheel is another important maintenance practice. Dust, debris, and metal particles can accumulate on the surface during use, reducing its effectiveness. Using a wire brush or specialized wheel cleaner to remove buildup helps maintain the wheel’s abrasive properties. However, avoid using excessive force or harsh chemicals that could damage the wheel’s bonding material. Keeping the surface clean helps maintain efficient grinding and reduces the chance of overheating, which can weaken the wheel.

Proper use is also key to maintaining angle grinder grinding wheels. Applying excessive pressure while grinding can cause the wheel to wear unevenly or overheat, leading to premature failure. Allowing the wheel to do the work with moderate pressure ensures better results and extends its life. It’s also important to use the right wheel for the material and task at hand. Different wheels are designed for specific materials such as metal, stone, or concrete, and using the incorrect type may damage both the wheel and the workpiece.

Storing angle grinder grinding wheels correctly is equally important to prolong their usability. The wheels should be kept in a dry, cool environment away from direct sunlight and moisture, which can degrade the bonding material and reduce wheel strength. Avoid storing wheels near chemicals or solvents that might affect their composition. Ideally, wheels should be stored flat or vertically in racks designed to prevent warping or deformation. Proper storage helps maintain the wheel’s shape and balance, which are essential for safe operation.

Temperature control is another factor in storage. Extreme temperatures can cause the wheel materials to expand or contract, which may result in cracks or other damage. Maintaining a stable room temperature in the storage area helps prevent such issues. Additionally, avoid stacking heavy items on top of grinding wheels, as excessive weight can lead to fractures or bending.

Handling angle grinder grinding wheels with care during transport and installation also contributes to their longevity. Dropping or banging the wheel can cause micro-fractures that may not be immediately visible but can compromise safety. When mounting the wheel on the angle grinder, make sure to follow manufacturer guidelines for proper installation torque and ensure the wheel is securely fastened. Incorrect installation can lead to imbalance and dangerous vibrations during operation.

It’s also useful to rotate grinding wheels periodically if you have multiple wheels in use. This practice ensures even wear across your collection, allowing you to make the most of each wheel’s lifespan. Keeping track of usage time and signs of wear helps plan timely replacements and avoid unexpected breakdowns.

Maintaining and storing angle grinder grinding wheels properly plays a vital role in their performance and safety. Regular inspection, careful cleaning, appropriate use, and proper storage conditions all contribute to extending the wheel’s lifespan. By adopting these practices, users can ensure reliable grinding results while minimizing risks. Taking good care of your grinding wheels ultimately supports a more efficient and safer working environment.

Eng

Eng  عربى

عربى