How Do Custom Grinding Wheels for Metal Improve Precision in Manufacturing?

2025.08.08

2025.08.08

Industry News

Industry News

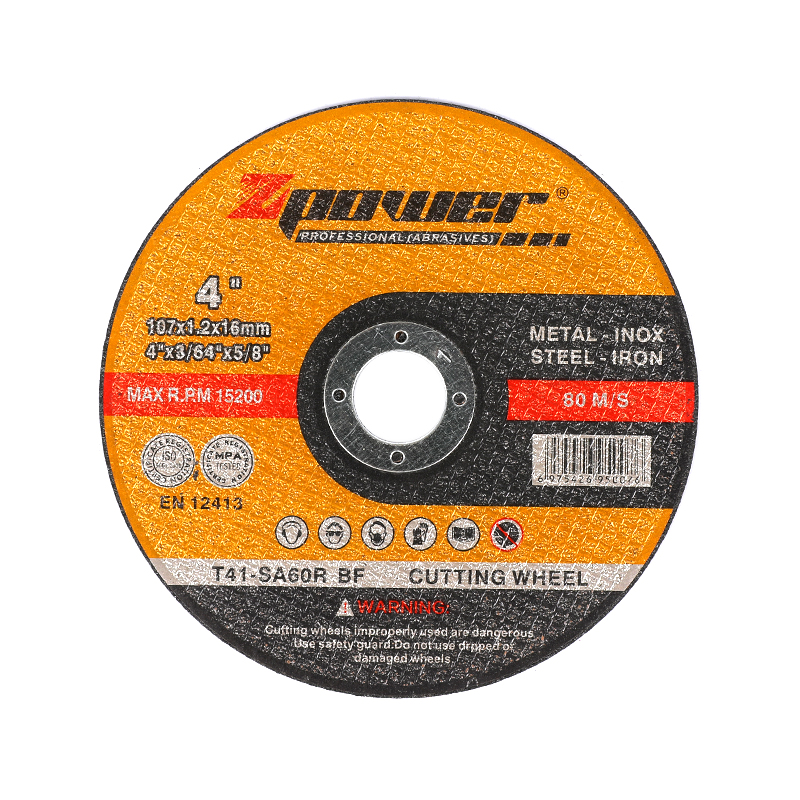

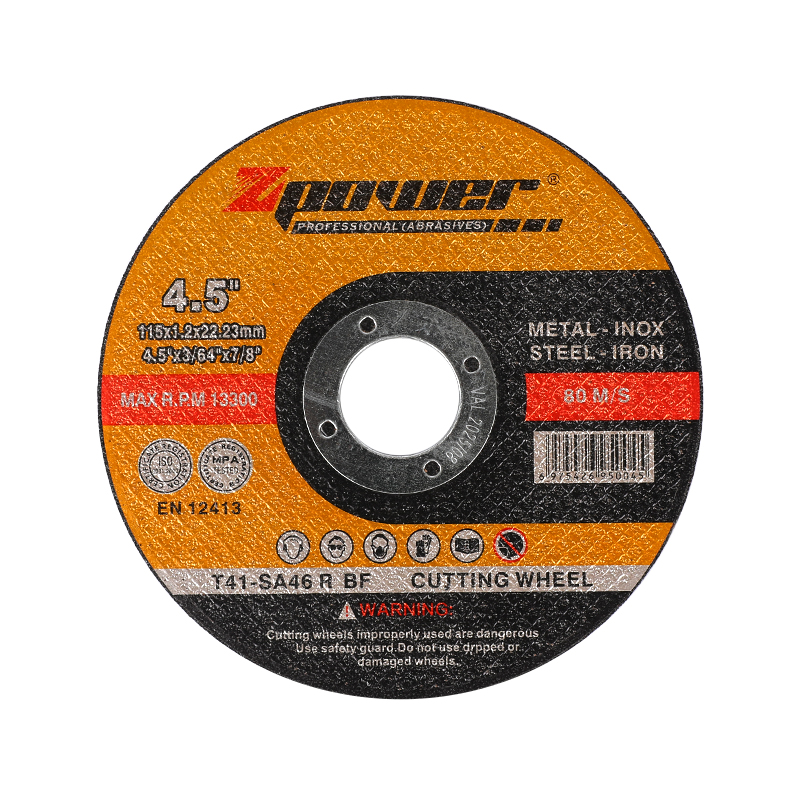

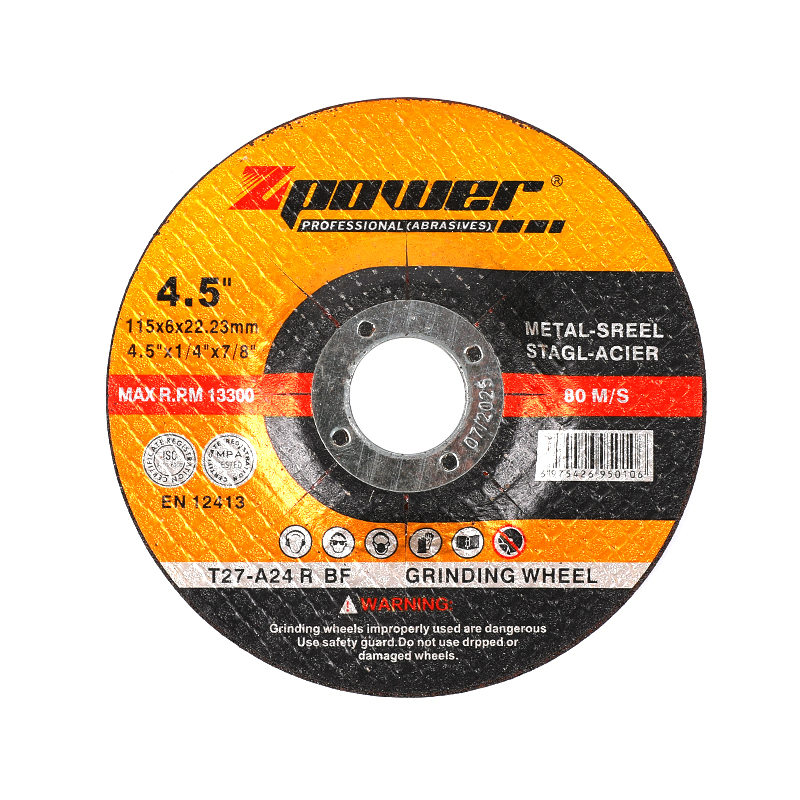

Grinding wheels are essential tools in metalworking, used to shape, finish, and smooth metal components across various industries. While standard grinding wheels serve many general purposes, custom grinding wheels for metal offer specific advantages when precision and efficiency are critical. By tailoring the wheel’s composition, size, and design to the unique requirements of a manufacturing process, these custom wheels contribute significantly to improved accuracy and product quality.

Tailoring Abrasive Material and Grit Size

One key factor in the precision of metal grinding is the abrasive material used in the wheel. Different metals and alloys respond better to specific abrasives. A custom grinding wheel for metal can be designed with the appropriate abrasive, such as aluminum oxide, silicon carbide, or diamond, depending on the hardness and characteristics of the workpiece.

Additionally, selecting the right grit size is essential. Finer grits produce smoother finishes and tighter tolerances, which are vital in precision manufacturing. Coarser grits, on the other hand, allow faster material removal but may sacrifice surface quality. Custom grinding wheels allow manufacturers to balance these factors based on the task, leading to more controlled and accurate grinding results.

Optimizing Wheel Bond and Structure

The bond that holds the abrasive grains together and the wheel’s internal structure also affect grinding precision. Custom grinding wheels for metal can feature bonds such as vitrified, resin, or metal, chosen according to the specific application and desired finish.

The wheel’s structure, including porosity and grain spacing, influences heat dissipation and chip clearance during grinding. Well-designed structures reduce thermal damage and prevent workpiece distortion, helping maintain dimensional accuracy. By customizing these aspects, manufacturers can reduce errors caused by overheating or uneven grinding.

Custom Sizing and Shaping for Specific Applications

Standard grinding wheels often come in fixed sizes and shapes, which may not perfectly suit all manufacturing setups. Custom grinding wheels for metal can be produced in specific diameters, thicknesses, and profiles to fit specialized machines or achieve unique grinding angles.

This customization ensures better contact between the wheel and the workpiece, leading to improved control and consistency. For example, wheels designed for cylindrical grinding, surface grinding, or intricate contouring can be optimized to enhance precision in those particular operations.

Enhanced Balance and Runout Control

Balance and runout are critical factors affecting the accuracy of grinding processes. Imbalances or excessive runout in a grinding wheel can cause vibrations, leading to uneven material removal and surface defects.

Custom grinding wheel manufacturers often provide wheels with tighter balance tolerances and runout specifications tailored to the client’s machinery. This careful manufacturing results in smoother operation and better repeatability, directly contributing to higher precision in metalworking.

Adapting to Specific Manufacturing Environments

Different manufacturing environments pose unique challenges, such as varying speeds, feed rates, coolant use, and machine rigidity. A custom grinding wheel for metal can be designed to perform optimally under these conditions.

For example, wheels intended for high-speed CNC grinders may require different bonding materials or reinforcement compared to those used in manual or lower-speed machines. This adaptability helps maintain consistent precision despite differing operational variables.

Custom grinding wheels for metal improve precision in manufacturing by allowing tailored abrasive composition, optimized bonding, specialized sizing, and strict balance control. These factors work together to enhance surface finish, dimensional accuracy, and overall process consistency. By selecting grinding wheels that are specifically designed for their metalworking needs, manufacturers can achieve better quality outcomes and more efficient operations. Customization in grinding wheels thus plays a valuable role in meeting the exacting demands of modern metal manufacturing.

Eng

Eng  عربى

عربى