Why Should You Choose Custom Sanding Discs for Specialized Projects?

2025.06.20

2025.06.20

Industry News

Industry News

When it comes to surface preparation, shaping, and finishing, the right abrasive tool can make a significant difference in both efficiency and results. For specialized or non-standard applications, custom sanding discs offer specific advantages over standard off-the-shelf products. From selecting the grit size to customizing the backing material and disc shape, these tailored solutions are designed to meet exact project requirements.

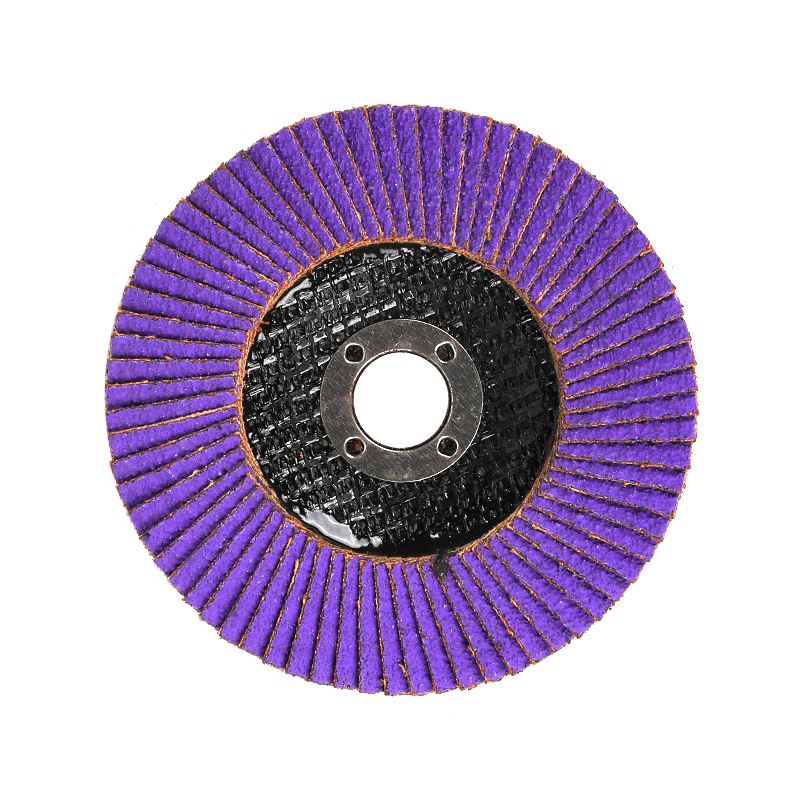

One of the main reasons professionals turn to custom sanding discs is the variety of materials they may need to work on. Whether it’s hardwood, metal, fiberglass, or a composite surface, different materials require specific abrasives to achieve consistent results. With customized options, users can select abrasive grains such as aluminum oxide, zirconia, silicon carbide, or ceramic, depending on the hardness and texture of the surface they are working with.

The backing material is another area where customization adds value. Depending on the application, users can choose from paper, cloth, film, or a combination of materials for strength, flexibility, or resistance to heat and moisture. For instance, sanding applications involving water or oil may benefit from waterproof backings, while dry, high-speed tasks might require more rigid options. By customizing the backing, custom sanding discs can be adapted for both hand-held tools and automated machines.

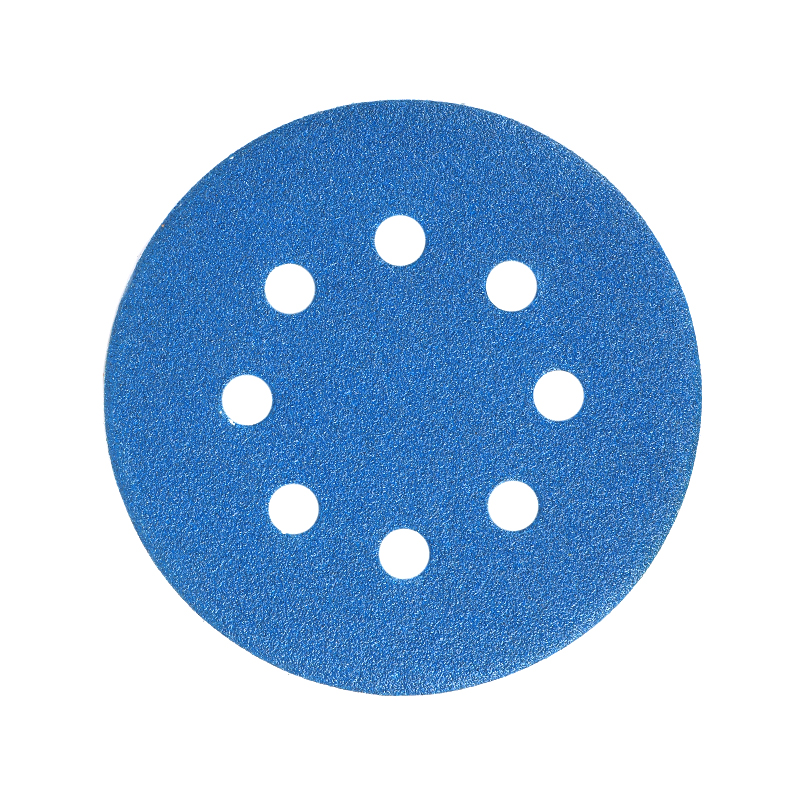

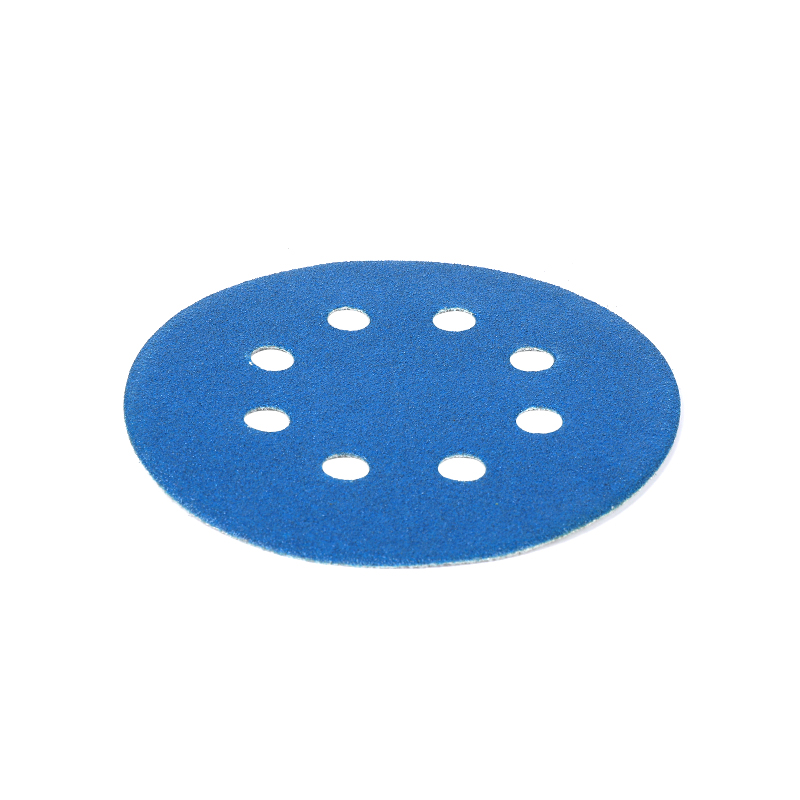

Another aspect where custom sanding discs make a difference is the size and shape of the disc. Standard round discs may not be suitable for all machinery or surface areas. Projects involving tight corners, irregular contours, or specialty equipment often require non-standard disc dimensions or perforation patterns. Customized discs can be produced in rectangular, triangular, or uniquely shaped formats that improve access and performance for specific needs.

The hole configuration for dust extraction is also an important consideration. Custom hole patterns help improve air flow and reduce heat buildup during extended sanding sessions. This not only enhances the sanding experience but also prolongs the life of the disc and the tool. For industries such as automotive refinishing or woodworking, where fine dust can affect both safety and finish quality, custom sanding discs offer clear advantages.

Additionally, businesses working on repeat or high-volume specialized tasks benefit from consistency. Ordering custom sanding discs ensures that every disc performs to the same specification, reducing variability in finish quality and tool wear. This reliability is particularly important in manufacturing environments where process control is critical.

Some manufacturers also offer branding options for custom sanding discs, allowing businesses to include logos or identifiers directly on the backing. This not only helps with inventory management but also enhances brand visibility when used in customer-facing services.

Custom sanding discs provide tailored solutions for projects that require specific abrasive properties, backing materials, sizes, and dust extraction configurations. Their adaptability helps ensure that sanding tools meet the unique demands of a task, improve efficiency, and maintain consistency. For professionals across industries, these customized abrasives offer a practical solution for meeting quality and productivity goals.

Eng

Eng  عربى

عربى