How Does Flap Wheel Construction Affect Its Performance?

2025.06.13

2025.06.13

Industry News

Industry News

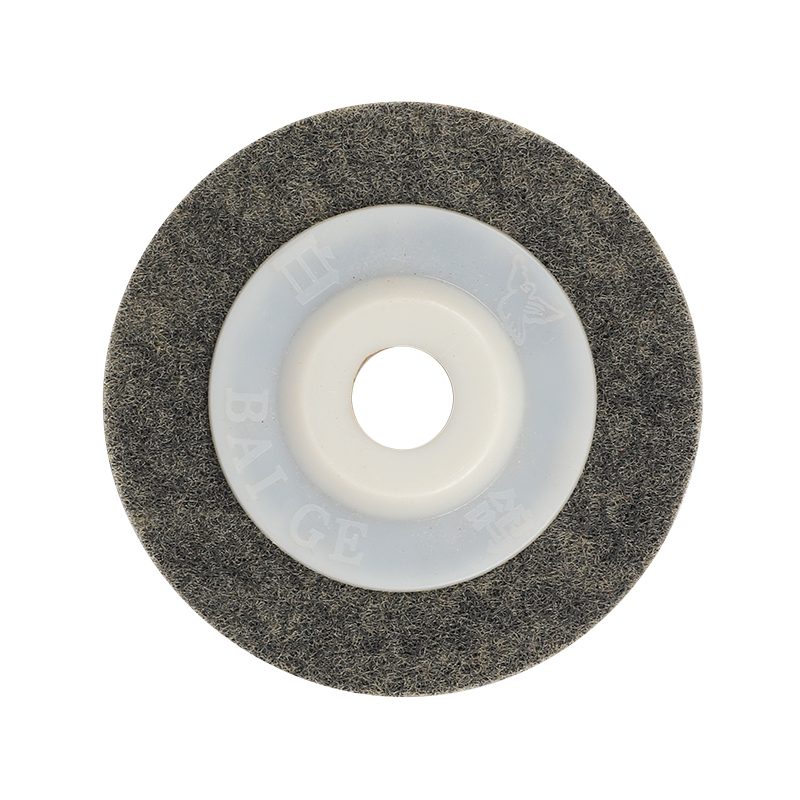

The flap wheel is a versatile abrasive tool widely used in surface finishing, blending, and light deburring. Its performance depends greatly on its construction, which includes the abrasive material, backing, density, grit size, and mounting system. Understanding how each component affects the tool's function can help users select the suitable flap wheel for their application.

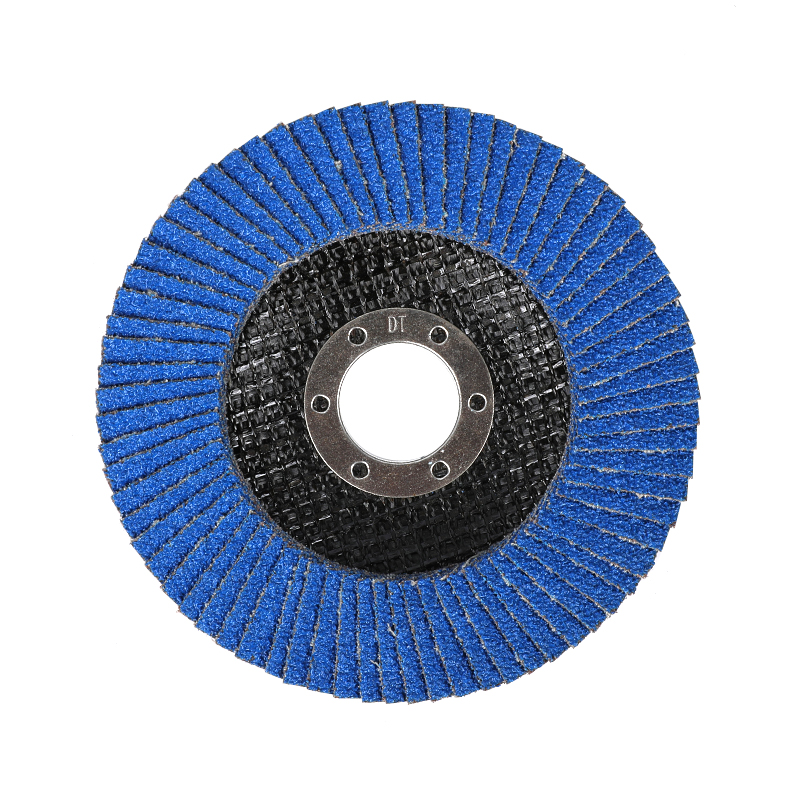

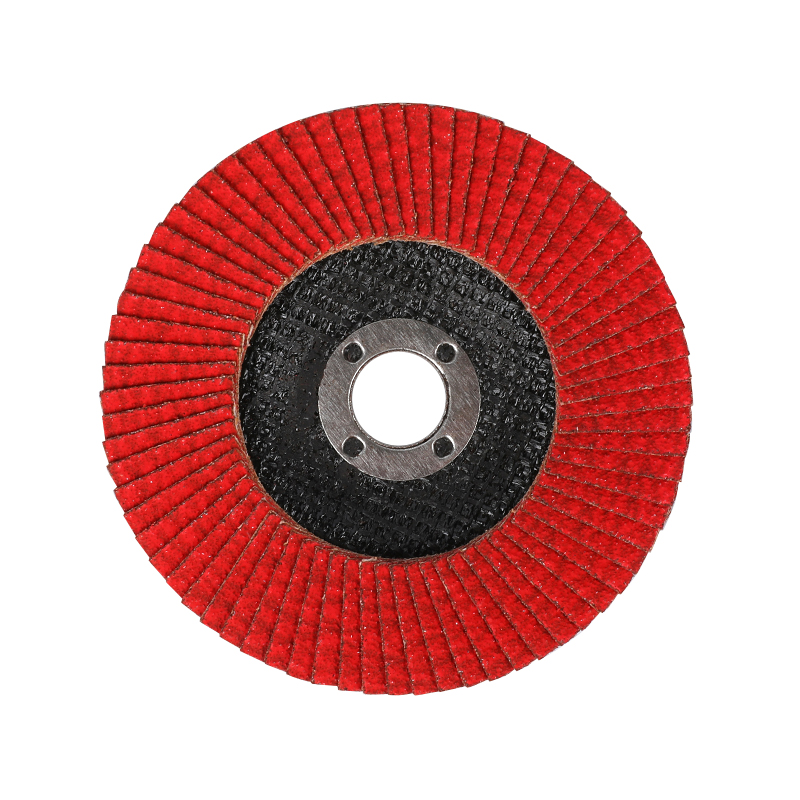

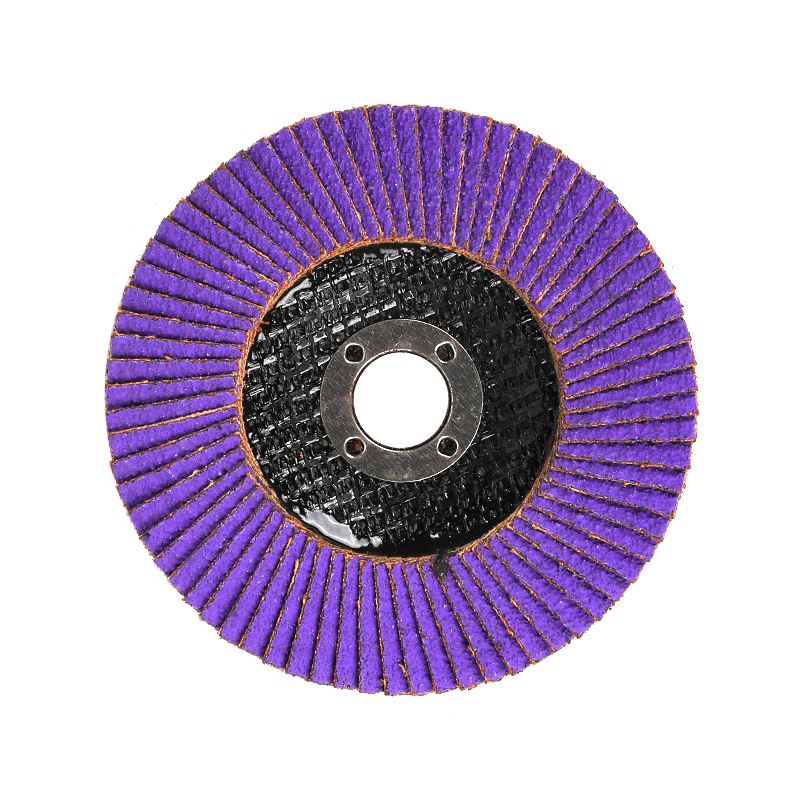

A flap wheel consists of multiple overlapping abrasive flaps arranged radially around a central hub. These flaps are typically made from coated abrasive materials like aluminum oxide, zirconia alumina, or ceramic. Each material type contributes differently to cutting ability and durability. For instance, aluminum oxide is a common choice for general-purpose applications, while zirconia is often selected for tougher metals due to its self-sharpening properties.

The backing material of each flap is another essential aspect of flap wheel construction. Common backings include cloth, polyester, or blended materials that offer varying levels of flexibility and strength. A more flexible backing allows the wheel to conform better to irregular surfaces, making it useful for contours or curved parts. Stiffer backings provide more aggressive material removal and are suitable for flat surfaces.

Flap density plays a significant role in determining the aggressiveness and longevity of the flap wheel. A higher flap density typically results in longer service life and smoother finishes, as more abrasive material is available for use. Conversely, a wheel with lower density can offer faster cutting action because of increased spacing between flaps, which helps reduce clogging and heat buildup.

Grit size is also crucial in assessing the performance of a flap wheel. Coarse grits, such as 40 or 60, are used for rapid material removal and initial surface conditioning. Fine grits, like 120 or 240, are better suited for final finishing and polishing. Choosing the appropriate grit ensures the desired surface finish without overworking the material or the tool.

The construction method—whether the flap wheel is mounted on a spindle, shaft, or has a through-hole—affects its compatibility with machines. Spindle-mounted flap wheels are ideal for hand-held tools and offer better control for precision tasks. Larger wheels with center holes are generally mounted on stationary equipment and are used for broader surface finishing work.\

Bonding technique and adhesive strength are often overlooked, but they directly affect the durability of the flap wheel. Poorly bonded flaps can loosen during operation, reducing efficiency and posing safety hazards. Well-constructed wheels use adhesives that hold the flaps securely even under continuous pressure and high speeds.

In addition to physical components, the design of the flap wheel affects heat dissipation and wear. Radial spacing between flaps allows air circulation during use, reducing the risk of overheating the workpiece. As each flap wears down, a fresh layer of abrasive is exposed, ensuring consistent performance throughout the tool’s life.

The performance of a flap wheel is closely linked to its construction details, including abrasive material, backing, density, grit size, and mounting method. By selecting the right combination of these features, users can achieve efficient, reliable results across a range of finishing and deburring tasks. Understanding these elements is essential for matching the flap wheel to the specific needs of a project.

Eng

Eng  عربى

عربى