Can Alumina Grinding Wheels Be Used for Both Wet and Dry Grinding?

2025.06.27

2025.06.27

Industry News

Industry News

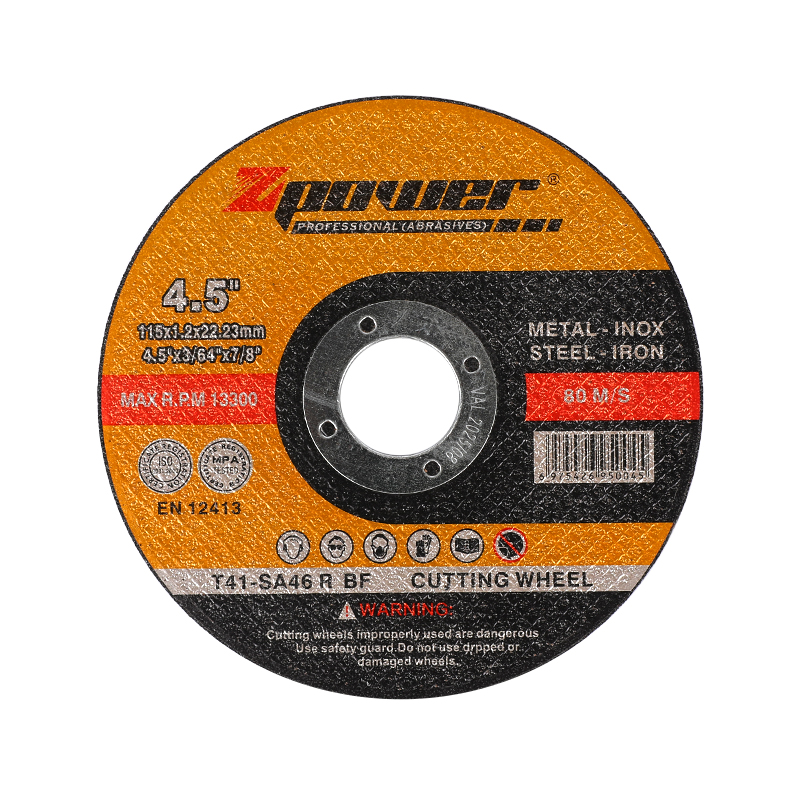

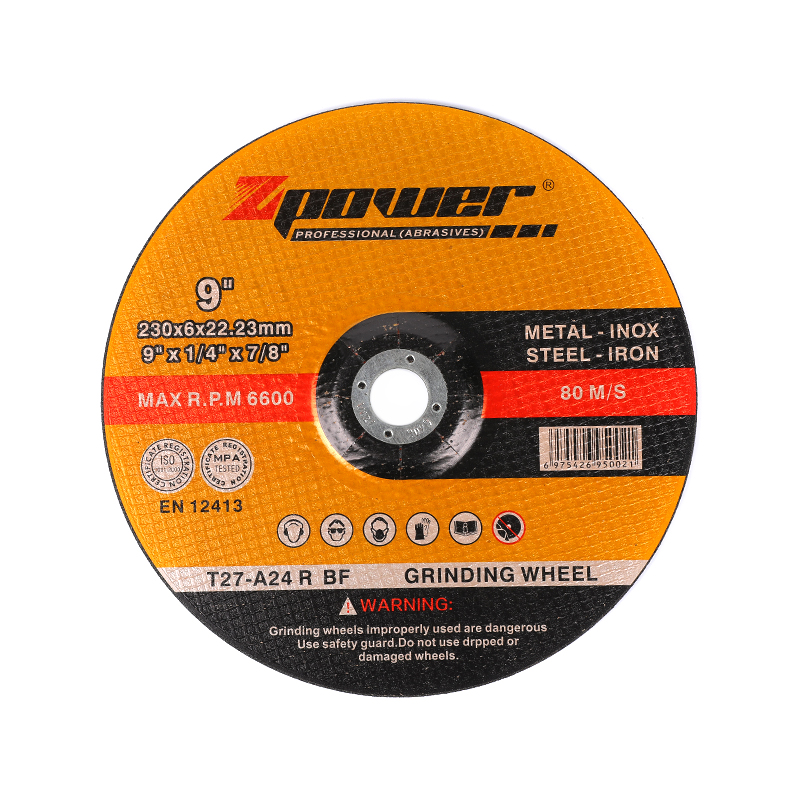

In various industrial settings, grinding plays a crucial role in shaping, finishing, and refining materials. One of the common abrasive tools used in such processes is the alumina grinding wheel. Known for its hardness and durability, this type of grinding wheel is often chosen for its ability to work with a broad range of metals and materials. A common question among operators and procurement teams is whether alumina grinding wheels are suitable for both wet and dry grinding applications.

To answer this question, it is essential to understand the composition and properties of an alumina grinding wheel. These wheels are typically made from aluminum oxide, a synthetic abrasive known for its toughness and heat resistance. They come in various grades and structures depending on the grinding application—ranging from coarse, aggressive cutting to fine surface finishing.

When it comes to dry grinding, the alumina grinding wheel performs efficiently in many standard applications. Its heat-resistant properties allow it to handle the friction and temperatures generated during dry contact with metal surfaces. This makes it a preferred choice for bench grinders, hand-held angle grinders, and other dry-use machinery. However, it's important to manage the heat generated during dry grinding, as excessive temperatures can affect both the wheel and the workpiece. In some cases, overheating may result in surface burns or material warping, especially in softer metals.

In contrast, wet grinding uses a coolant—typically water mixed with a lubricant or chemical additive—to control the heat produced during grinding. Wet grinding helps reduce thermal stress on both the alumina grinding wheel and the material being processed. It also helps flush away debris, enhancing surface finish and extending the life of the grinding wheel. Many industrial environments, especially in precision machining and tool making, use wet grinding for more accurate and consistent results.

The good news is that most alumina grinding wheels are compatible with both wet and dry grinding. However, compatibility may vary depending on the wheel’s bonding material, structure, and intended application. For instance, vitrified bonded wheels generally tolerate both wet and dry use, while resin-bonded wheels might be more sensitive to heat buildup and could benefit from wet conditions.

When selecting an alumina grinding wheel for dual-purpose use, it is advisable to consult the manufacturer’s specifications. Not all wheels are designed to withstand continuous exposure to coolant, especially if used with high-speed equipment. Additionally, factors such as wheel hardness, grit size, and machine type should be considered to ensure the most effective grinding process.

Safety is another concern in both grinding environments. When using a dry grinding setup, ensuring proper ventilation and dust collection is important. For wet grinding, preventing fluid splashes and corrosion requires attention to maintenance and cleanup routines.

The alumina grinding wheel is a versatile tool that can be used for both wet and dry grinding under the right conditions. Its ability to handle different environments makes it a valuable component in many fabrication and machining processes. Understanding its characteristics and using it within recommended parameters can help achieve consistent, safe, and effective grinding results.

Eng

Eng  عربى

عربى