What Factors Affect the Performance of Grinding Wheels for Metal?

2025.06.06

2025.06.06

Industry News

Industry News

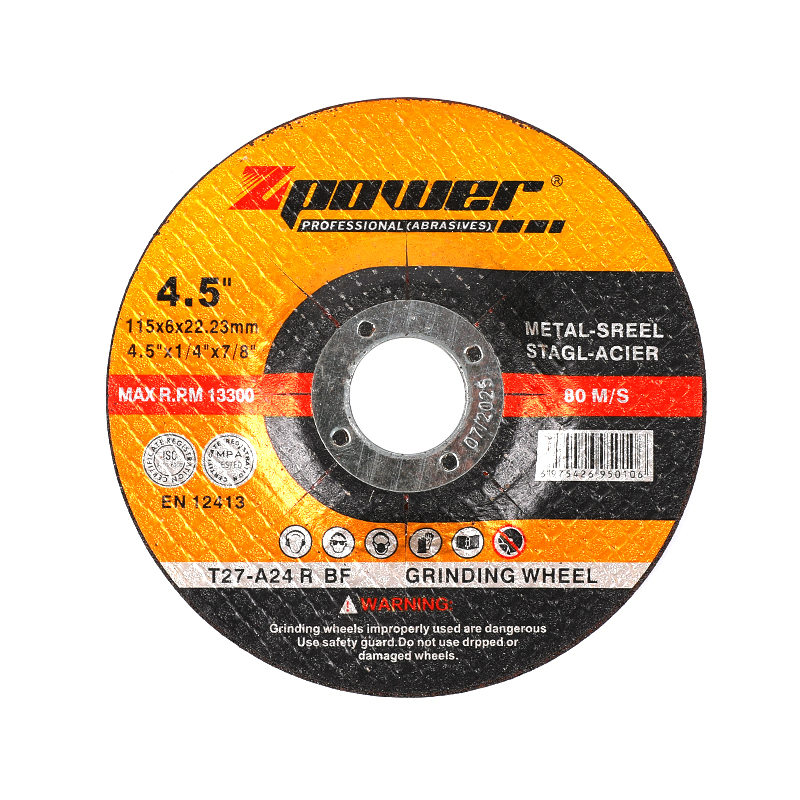

Grinding wheels for metal are essential tools in manufacturing, construction, and metalworking industries. Their primary function is to remove material from metal surfaces through abrasion, allowing workers to shape, finish, or prepare metals for welding, painting, or further machining. However, the performance of these wheels can vary depending on several key factors. Understanding what influences the performance of grinding wheels for metal helps professionals select the right wheel for their specific application and achieve consistent results.

One major factor that affects the performance of grinding wheels for metal is the abrasive material used in their construction. Common abrasive materials include aluminum oxide, silicon carbide, zirconia alumina, and ceramic grain. Each of these abrasives has different properties suitable for various metal types. For instance, aluminum oxide is widely used for grinding steel, while silicon carbide is often used on non-ferrous metals. The compatibility between the abrasive and the metal being worked on greatly influences the efficiency and surface finish achieved.

Another significant factor is grain size, which refers to the size of the abrasive particles on the wheel. Coarser grains (lower numbers) are used for rapid material removal, while finer grains (higher numbers) are preferred for achieving smoother finishes. Choosing the correct grain size ensures that the grinding wheels for metal perform as intended, whether for aggressive grinding or precision finishing.

The bond type holding the abrasive grains together also affects how the wheel behaves during use. Vitrified bonds are common and offer strength and rigidity, while resin bonds provide flexibility and are better suited for applications requiring reduced heat generation. The choice of bond type impacts the cutting speed, surface finish, and heat resistance of the wheel.

Wheel hardness, or the strength of the bond between abrasive grains, determines how quickly the grains break away and expose fresh cutting edges. Softer wheels release worn grains faster and are often used for harder metals, while harder wheels retain their shape longer and are used on softer metals. Improper hardness selection may cause glazing, where the wheel becomes smooth and loses its cutting ability.

Wheel shape and size also play a role in the performance of grinding wheels for metal. Different shapes, such as straight, cup, or dish wheels, are designed for various types of surface and edge grinding. The size of the wheel affects coverage and contact area with the metal surface, influencing both efficiency and control.

The speed and pressure applied during grinding are additional factors that impact performance. Operating a grinding wheel above its rated speed can cause a reduced lifespan or even safety hazards. Similarly, applying too much pressure can cause overheating, while insufficient pressure may result in inefficient cutting.

Coolant use is another important consideration. In many grinding operations, a coolant or lubricant is used to reduce heat, minimize dust, and improve surface quality. The use of coolant can significantly extend the life of grinding wheels for metal and ensure smoother operation.

Wheel maintenance affects long-term performance. Regular dressing of the wheel restores its cutting ability by removing clogged or dulled grains and exposing fresh abrasives. Proper storage, handling, and inspection also prevent damage and maintain consistent performance.

In conclusion, the performance of grinding wheels for metal depends on multiple interrelated factors, including abrasive material, grain size, bond type, wheel hardness, shape, speed, pressure, and maintenance. By understanding and controlling these variables, users can achieve more efficient and accurate results in their grinding applications.

Eng

Eng  عربى

عربى