What Are the Advantages of Custom Flap Discs Over Standard Abrasives?

2025.05.26

2025.05.26

Industry News

Industry News

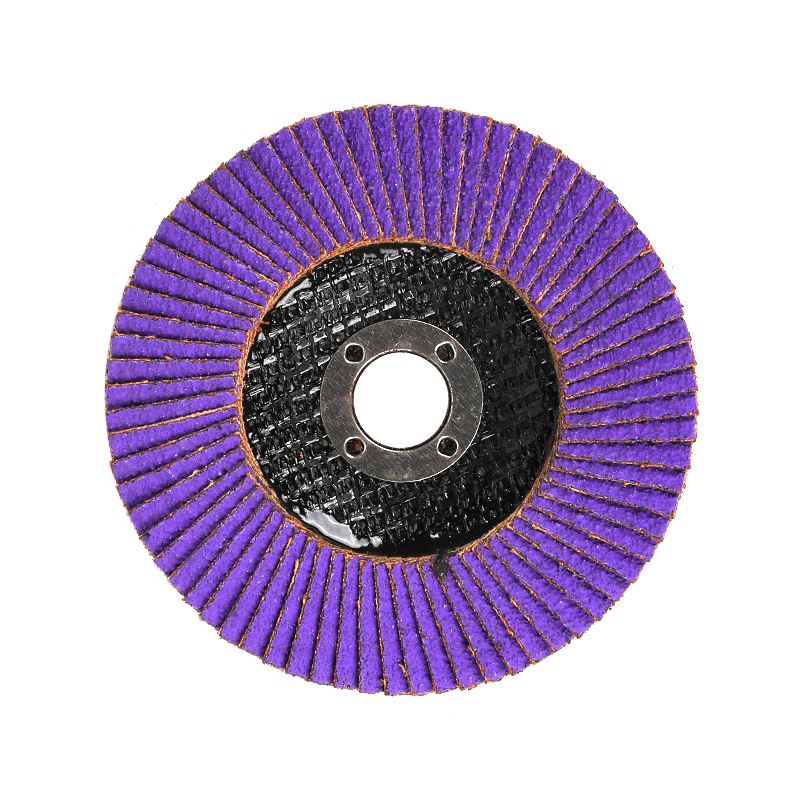

Flap discs are widely used in industries such as metalworking, construction, and automotive for grinding, blending, and polishing tasks. Traditionally, standard abrasives have been the go-to solution for many applications. However, with the rise of custom flap discs, manufacturers and users alike are beginning to see the distinct advantages these tailored products offer. Custom flap discs provide several key benefits over standard abrasives, such as improved performance, better material compatibility, extended lifespan, and increased flexibility in design.

Tailored Performance for Specific Applications

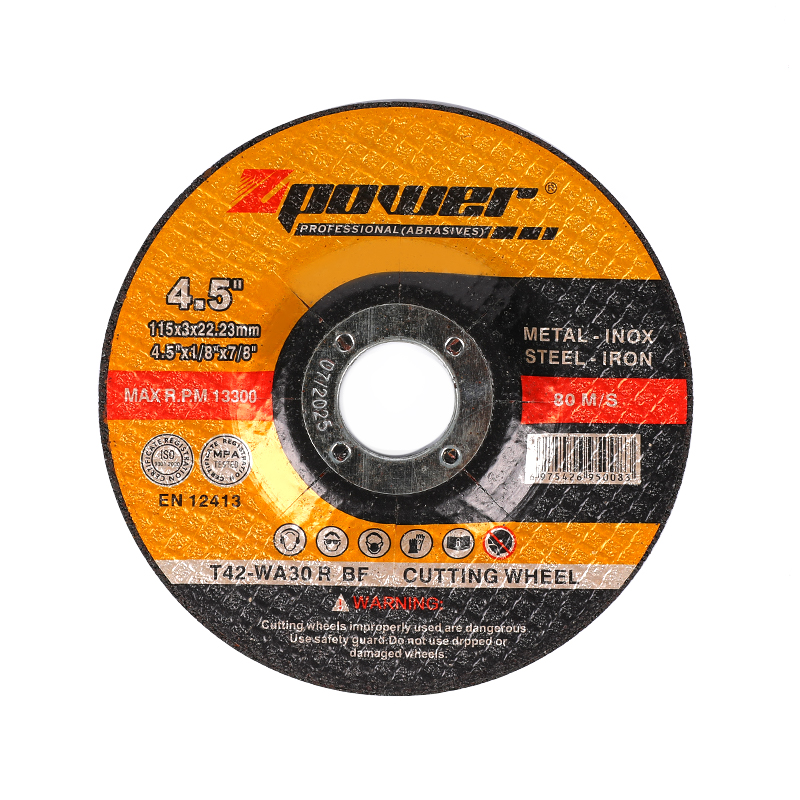

One of the primary advantages of custom flap discs is their ability to be designed for specific applications. Standard abrasives are usually made for general-purpose tasks, and while they can work for a range of materials and jobs, they may not be the fit for specialized tasks. Custom flap discs, on the other hand, can be made with specific abrasives, such as aluminum oxide or zirconia, which are optimized for certain materials like stainless steel or aluminum. By customizing the disc for the exact application, users can achieve better results, whether they’re grinding, blending, or finishing surfaces.

Enhanced Material Compatibility

Standard abrasives are often made from a one-size-fits-all approach, which may not be ideal for all materials. For example, using a standard flap disc on a material that is too soft or too hard could lead to poor results, excessive wear, or even damage to the workpiece. Custom flap discs are created with specific abrasive materials and backing that complement the work material. For instance, when working with hard metals, a custom flap disc with a tougher abrasive material will provide better performance and efficiency. Customization allows users to choose the ideal combination of abrasives and materials for their particular job, ensuring a smoother and more accurate finish.

Extended Lifespan and Reduced Downtime

Another significant advantage of custom flap discs is their extended lifespan compared to standard abrasives. When a disc is tailored to a particular task, it can work more efficiently and last longer, reducing the frequency of replacements. For example, a custom flap disc designed for heavy-duty grinding will maintain its abrasive properties for a longer period, reducing the need for constant changes and reducing downtime in production. This can result in both time and cost savings, making the investment in custom flap discs worthwhile over time.

Increased Flexibility in Design

Custom flap discs offer greater flexibility in terms of size, shape, and design. Manufacturers can create discs with specific dimensions or adapt them to fit different machinery. The backing material and abrasive grain can also be tailored to meet the exact requirements of a project. This flexibility is particularly useful in industries that require specialized tasks, such as automotive or aerospace, where precision and attention to detail are critical. By having access to customized solutions, businesses can optimize their production lines, enhance productivity, and meet demanding project specifications.

Improved Safety and Precision

Custom flap discs can also provide improved safety and precision when compared to standard abrasives. The precise design and material selection reduce the risk of premature wear, overheating, or disc breakage during use. Custom solutions often incorporate features such as better heat dissipation and more durable backing materials, which result in a safer and more stable grinding or polishing process.

The advantages of custom flap discs over standard abrasives are clear. By offering tailored performance, improved material compatibility, extended lifespan, increased design flexibility, and enhanced safety, custom flap discs provide businesses with a more efficient and cost-effective solution for their grinding and finishing tasks.

Eng

Eng  عربى

عربى