What Factors Affect Prices From Alumina Grinding Wheel Factories?

2025.11.24

2025.11.24

Industry News

Industry News

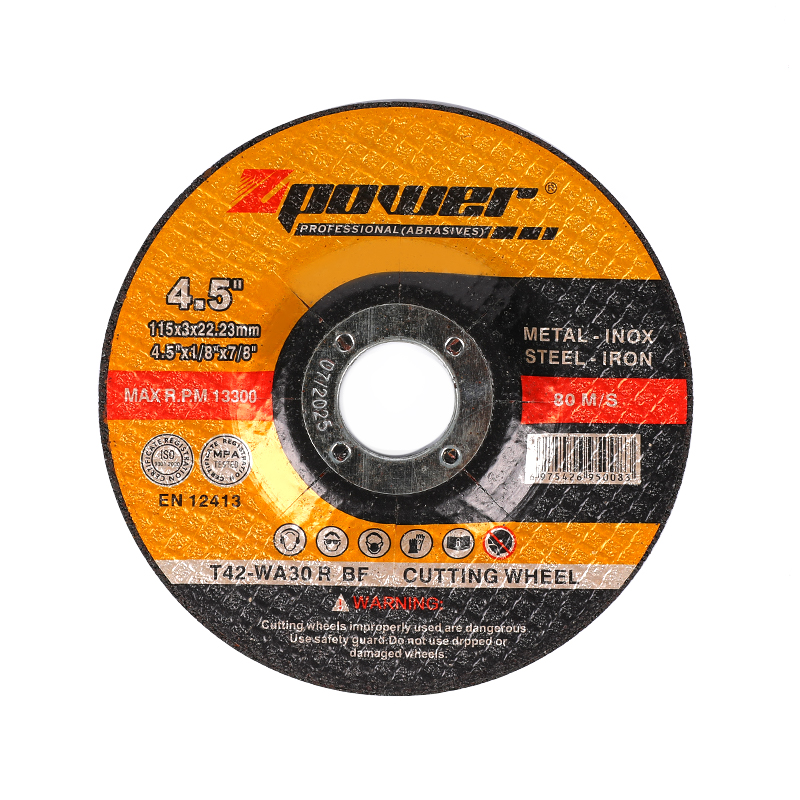

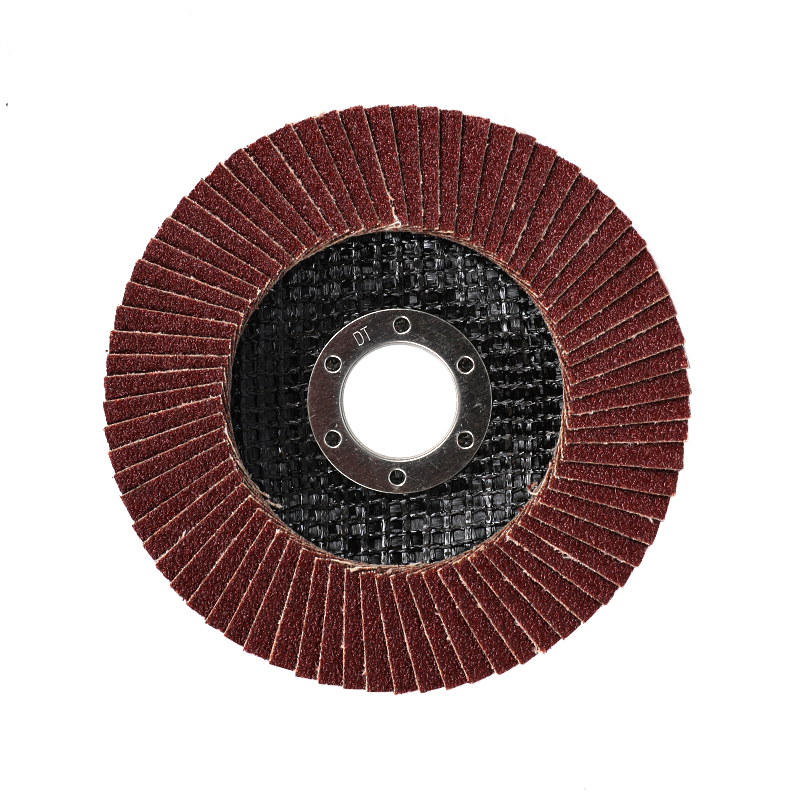

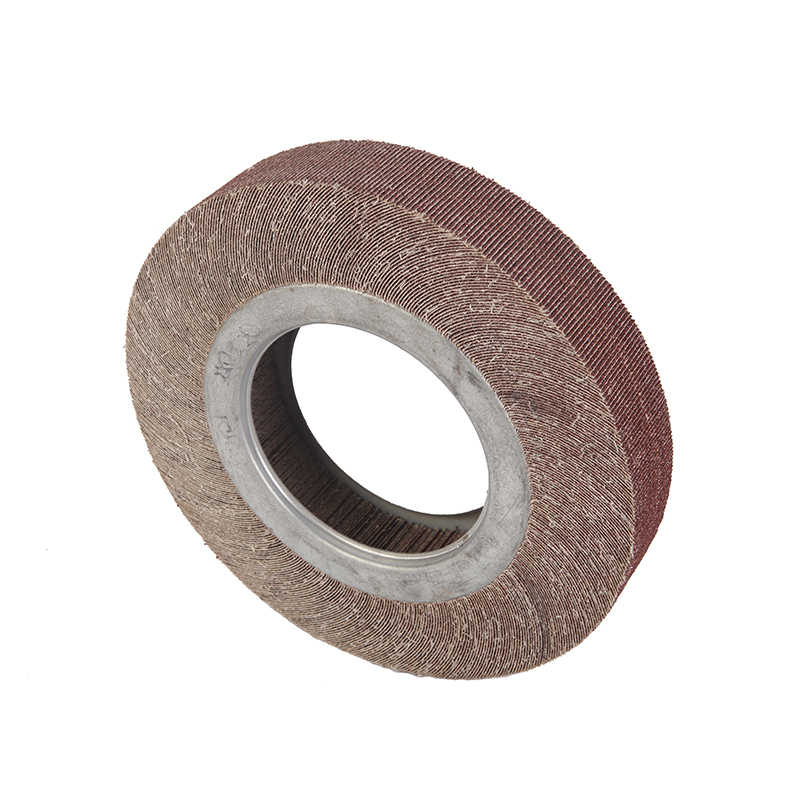

Alumina grinding wheels are essential tools in metalworking, construction, and manufacturing industries. When purchasing these wheels directly from an Alumina Grinding Wheel Factory, buyers often notice that prices can vary significantly.

Material Quality

The quality of raw materials is one of the primary factors affecting prices. High-quality alumina, combined with strong bonding agents, ensures the durability and performance of grinding wheels. Factories that use premium materials often charge more because the wheels last longer and maintain their grinding efficiency. On the other hand, lower-cost wheels may use less refined alumina or weaker bonding materials, which can reduce the lifespan and effectiveness of the product.

Manufacturing Process

The production process plays a significant role in determining costs. Some Alumina Grinding Wheel Factories use advanced machinery and automated production lines to ensure consistent quality and precision. Others may rely more on manual processes or less sophisticated equipment, which can affect both cost and performance. The level of precision required, such as specific wheel dimensions or tight tolerances, can also impact the final price.

Wheel Specifications

Different specifications of grinding wheels influence their cost. Factors such as wheel diameter, thickness, grit size, and hardness all contribute to pricing differences. Larger or thicker wheels require more materials and longer production time, which naturally increases the price. Similarly, wheels with finer grit or specialized hardness levels are often more expensive due to the additional processing and quality control involved.

Production Volume and Customization

The quantity of wheels ordered can affect pricing as well. Bulk orders often benefit from lower per-unit costs, while small or customized orders may carry higher prices. Customization, such as unique shapes, specific bonding formulas, or specialized abrasives, requires extra effort and resources from the factory. Buyers requesting these custom features should expect higher prices compared to standard products.

Labor and Operational Costs

Labor costs at the factory's location also influence the final price of alumina grinding wheels. Factories in regions with higher wages or stricter labor regulations may charge more to cover operational expenses. In addition, energy costs, equipment maintenance, and quality control measures are reflected in the pricing structure. Factories that invest in training and skilled labor to maintain high standards may have slightly higher prices but often provide more reliable products.

Shipping and Logistics

Shipping costs can also affect the overall price, especially for international buyers. Transporting heavy or fragile grinding wheels requires careful packaging and handling, which adds to the cost. Some factories include logistics in their pricing, while others list it separately, so buyers should consider these expenses when evaluating quotes.

Prices from an Alumina Grinding Wheel Factory are influenced by multiple factors, including material quality, manufacturing process, wheel specifications, order volume, labor costs, and logistics. Understanding these elements helps buyers assess whether a higher-priced wheel offers better value or if a lower-cost option meets their needs. By considering both the technical and operational aspects of production, businesses can make informed choices and select alumina grinding wheels that provide reliable performance without unexpected costs.

Eng

Eng  عربى

عربى