How Can an Alumina Grinding Wheel Factory Support Industrial Needs?

2025.12.05

2025.12.05

Industry News

Industry News

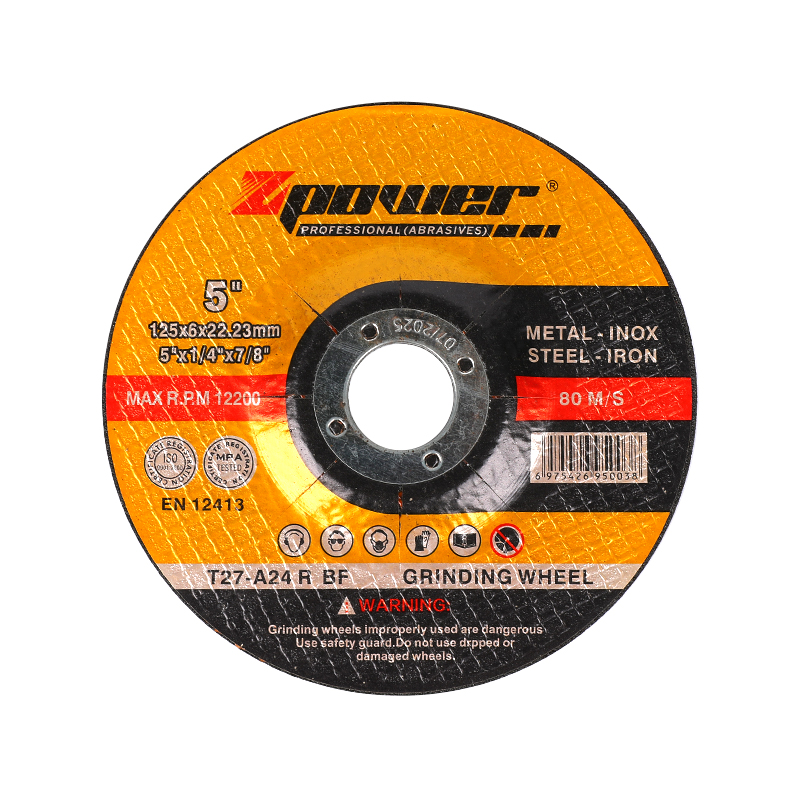

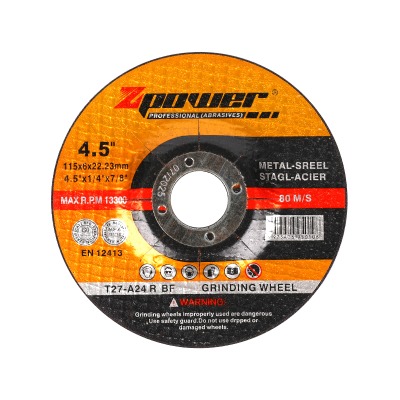

Alumina grinding wheels are widely used in industries ranging from metal fabrication to construction and woodworking. These tools are known for their durability and ability to grind, cut, or polish hard materials efficiently. A reliable alumina grinding wheel factory plays a crucial role in producing consistent and high-quality grinding wheels that meet the demands of both industrial and individual users.

By exploring how such a factory operates, buyers can better understand production standards, customization options, and safety practices.

Production Process: From Raw Materials to Finished Wheels

An alumina grinding wheel factory starts with selecting the right raw materials. Alumina, or aluminum oxide, is carefully measured and mixed with bonding agents that determine the hardness and cutting efficiency of the wheel.

Next, the mixture is molded and pressed into the desired shape, followed by a firing process at high temperatures to ensure strength and durability. Each wheel is inspected for uniformity, density, and balance. This meticulous process ensures that the grinding wheels perform reliably under various conditions.

Customization and Versatility

One advantage of sourcing from an alumina grinding wheel factory is the ability to customize products according to specific requirements. Factories can produce wheels in various sizes, grit levels, and bonding types, depending on the application.

For businesses, this flexibility is essential when manufacturing components that require precise surface finishes. For individual users, it allows for choosing the right wheel for home workshops or small-scale projects.

Safety and Compliance

Safety is a critical factor in grinding operations. A reputable alumina grinding wheel factory ensures that each wheel meets safety standards, including balance, structural integrity, and resistance to cracking during use.

Many factories also adhere to regional safety certifications and guidelines, which help reduce workplace accidents and improve overall reliability. For buyers, understanding the factory's quality control measures provides confidence in the purchased product.

Applications Across Industries

Alumina grinding wheels produced by a specialized factory serve various industries:

- Metalworking: Cutting, shaping, and polishing metals with precision.

- Construction: Smoothing concrete surfaces and sharpening tools.

- Automotive: Polishing and finishing parts in workshops and assembly lines.

- Woodworking: Creating smooth finishes on wooden components.

The consistent quality from an alumina grinding wheel factory ensures that these tasks can be completed efficiently and safely.

Choosing the Right Factory

Selecting the appropriate alumina grinding wheel factory involves considering several factors:

- Production Capacity: Can the factory handle bulk orders or large-scale industrial needs?

- Quality Assurance: Are there thorough inspection and testing procedures?

- Customization Options: Can the factory produce wheels to specific sizes, grits, and bonds?

- Delivery and Support: Does the factory offer timely shipping and after-sales support?

Understanding these aspects helps businesses and individual buyers make informed decisions, reducing potential delays and quality issues.

Benefits for Businesses and Individual Users

For businesses, partnering with a trusted alumina grinding wheel factory provides a reliable supply of high-quality wheels that support consistent production. Bulk orders can often be tailored to specific requirements, reducing costs and improving workflow efficiency.

Individual users benefit from easy access to durable and versatile grinding wheels suitable for personal workshops, hobby projects, or home repair tasks. By understanding how a factory operates, users can select the most suitable wheels for their intended applications.

An alumina grinding wheel factory plays an essential role in producing durable and precise grinding tools for a wide range of industries and personal uses. From material selection to production, customization, and safety compliance, these factories ensure that each wheel meets quality standards and performance expectations.

Whether you are a business purchasing in bulk or an individual looking for reliable workshop tools, knowing how a factory operates can guide better purchasing decisions. By focusing on quality, versatility, and safety, an alumina grinding wheel factory supports consistent and effective grinding results for various applications.

Eng

Eng  عربى

عربى