How Do Grinding Wheels Manufacturers Adapt to Market Demands?

2025.11.21

2025.11.21

Industry News

Industry News

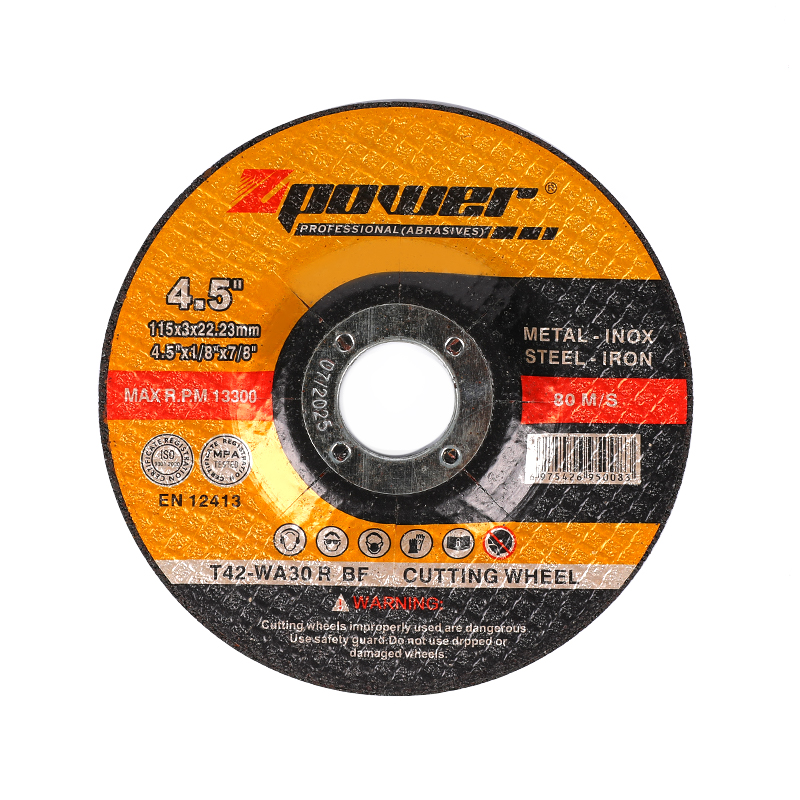

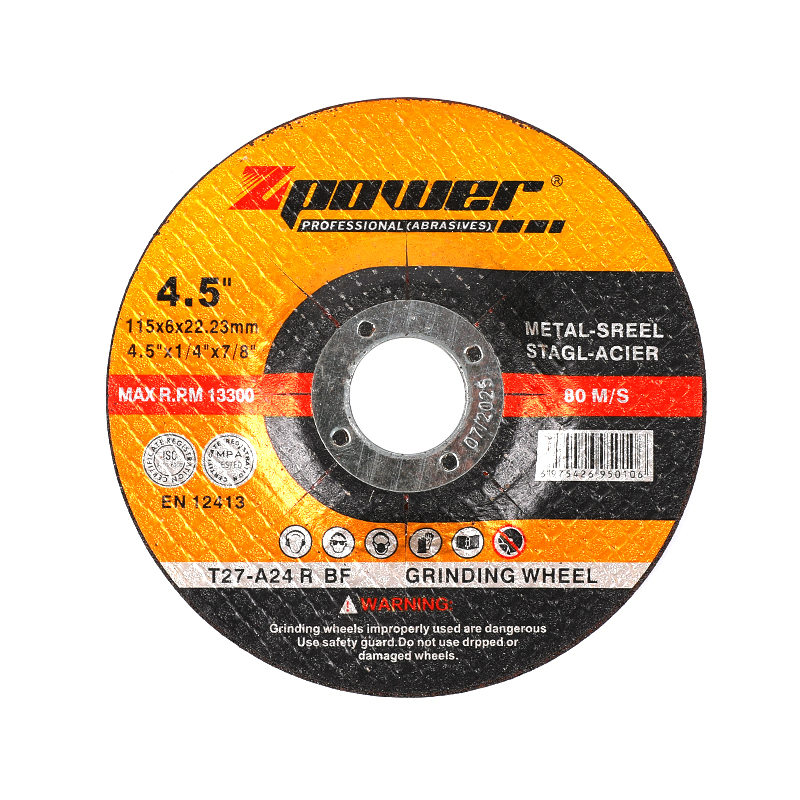

Grinding wheels are essential components in many industrial processes, from metal fabrication to woodworking. The demand for different types of grinding wheels evolves constantly, influenced by changes in materials, production techniques, and customer requirements. Grinding wheels manufacturers need to stay flexible and responsive to remain competitive.

Understanding Customer Needs

A key approach for Grinding Wheels Manufacturers is closely monitoring customer needs. Different industries require different wheel specifications, such as grit size, hardness, bonding type, and shape. Manufacturers often maintain open communication channels with clients to understand these requirements. Customization is a common solution, where manufacturers adjust wheel composition, size, or design to match specific production applications. This responsiveness ensures that the products meet the operational needs of diverse customers. Additionally, some manufacturers conduct regular surveys or on-site visits to gather feedback, helping them refine designs and anticipate future demands.

Incorporating Material Innovations

Grinding wheels rely on abrasives and bonding materials to function effectively. As new materials emerge in industries like automotive, aerospace, or stainless steel fabrication, manufacturers adjust their product lines to accommodate these changes. For instance, adapting wheels for high-strength alloys or composite materials requires experimenting with different abrasive types and bonding techniques. By staying informed about material trends, Grinding Wheels Manufacturers ensure their products remain relevant and capable of handling evolving industrial challenges. Some factories also invest in research and development to explore alternative abrasives or environmentally friendly bonding materials, reflecting both innovation and sustainability.

Streamlining Production Processes

Efficiency in production is another way manufacturers respond to market demands. Modern Grinding Wheels Manufacturers adopt flexible production lines that can quickly switch between different wheel types and specifications. Automation, modular equipment, and quality control systems help maintain consistent product performance while allowing for faster adjustments to changing orders. Streamlined processes also help manufacturers reduce lead times, which is increasingly important as clients expect faster delivery and higher reliability. Factories that can adjust production schedules dynamically are better positioned to respond to sudden spikes in demand or custom orders.

Emphasizing Quality and Compliance

Adapting to market demands isn't just about speed or variety; quality and safety standards are critical. Grinding Wheels Manufacturers often comply with international certifications and industry standards to meet the expectations of global clients. Regular testing of product performance, durability, and safety ensures that the wheels function as intended in different operational environments. High-quality products strengthen client trust and help manufacturers maintain a steady market presence even amid shifting demands. Some manufacturers also implement traceability systems, allowing clients to track production batches and ensure consistent quality.

Offering Technical Support and Consultation

In addition to physical products, manufacturers often provide technical support to assist clients in selecting the right grinding wheels. Consultation services help customers choose appropriate grit, wheel shape, and bonding materials based on their specific processes. This advisory approach strengthens relationships, encourages repeat business, and positions the manufacturer as a responsive partner rather than just a supplier. By offering training sessions or maintenance tips, some manufacturers also help clients optimize the performance and lifespan of their grinding wheels.

Grinding Wheels Manufacturers adapt to market demands by understanding customer needs, incorporating material innovations, streamlining production, maintaining quality standards, and offering technical support. Their ability to remain flexible and responsive ensures that they can meet the changing requirements of various industries. For businesses relying on grinding operations, working with a manufacturer that adapts effectively to market trends can lead to more efficient production, better product performance, and reliable support. Staying engaged with manufacturers who continuously improve their processes and products is an effective way to maintain a competitive edge in industrial operations.

Eng

Eng  عربى

عربى