How Do Grinding Discs Suppliers Ensure the Quality of Their Products?

2025.05.23

2025.05.23

Industry News

Industry News

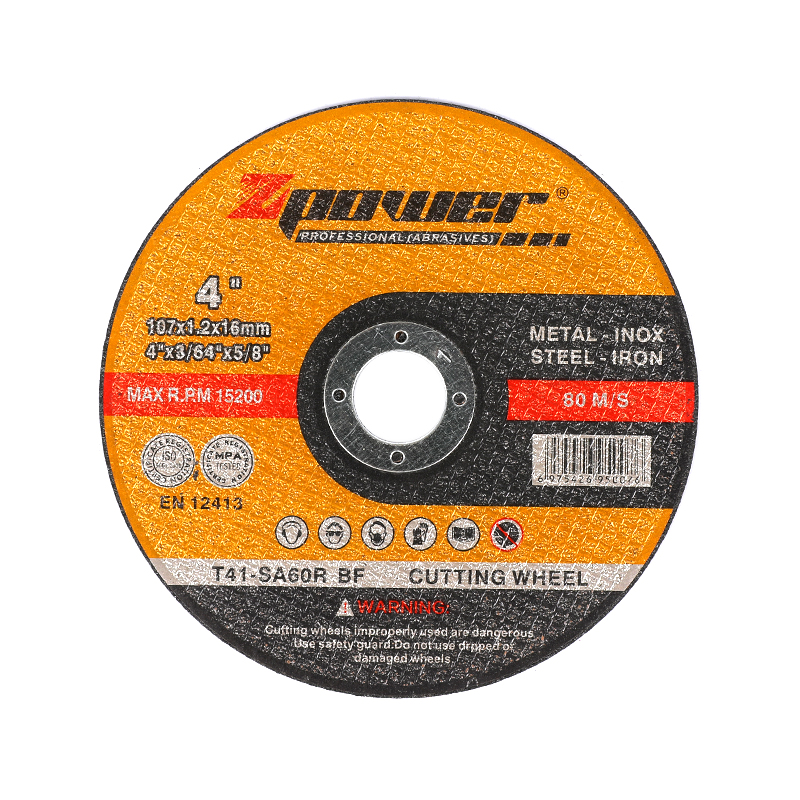

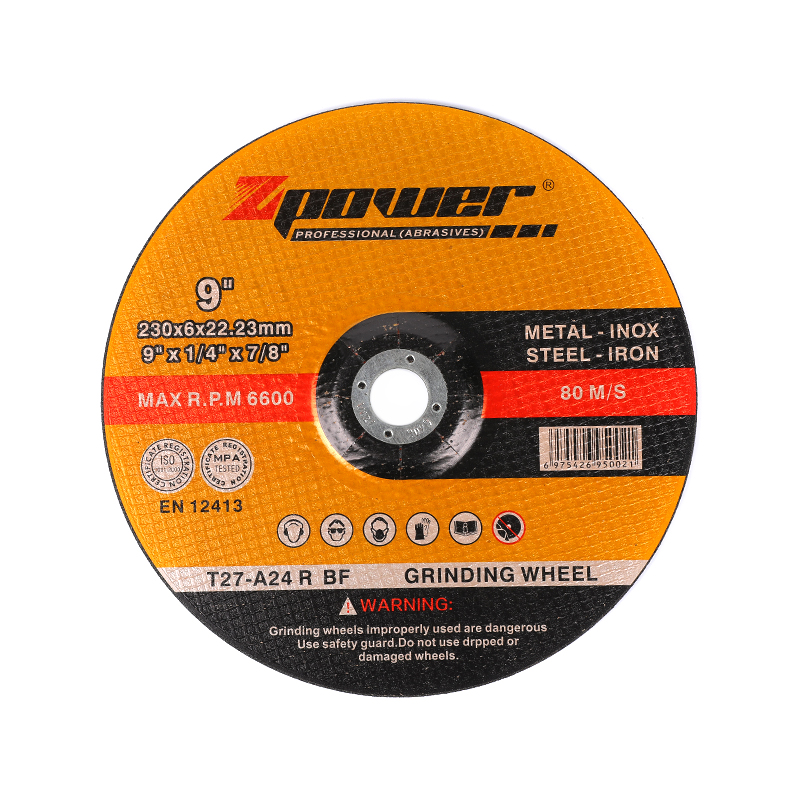

Grinding discs are essential tools used in various industries, from metalworking to construction, for tasks such as cutting, grinding, and polishing. The quality of these discs plays a critical role in ensuring efficient operations and a smooth finish on materials. As a result, grinding discs suppliers must take several steps to ensure their products meet the necessary standards. These steps involve strict material selection, testing procedures, adherence to industry regulations, and effective quality control processes.

Material Selection

One of the primary ways grinding discs suppliers ensure product quality is through careful material selection. The base materials used for manufacturing grinding discs, such as abrasives, resins, and binders, must meet specific standards to ensure durability and performance. Suppliers often source high-quality raw materials that are capable of withstanding the intense pressures and temperatures experienced during grinding tasks. By selecting materials that are both strong and stable, suppliers can create grinding discs that provide consistent results.

Manufacturing Process

The manufacturing process is another vital aspect in maintaining product quality. Most grinding discs suppliers follow established production techniques to ensure consistency and reliability. This includes monitoring the precise proportions of abrasives and binders used, as well as controlling the temperature and pressure during the pressing and curing processes. During production, automated systems are often used to ensure that each disc is shaped and treated according to the specified standards. By investing in advanced equipment and adhering to strict guidelines, grinding discs suppliers can produce discs with uniform performance characteristics.

Quality Control and Testing

To guarantee the reliability of their products, grinding discs suppliers perform a series of quality control tests throughout the production process. These tests include evaluating the disc’s strength, hardness, and resistance to wear. Suppliers often use testing methods such as stress testing, fatigue testing, and abrasive wear testing to measure how well a grinding disc holds up under pressure and over extended periods of use. These tests help suppliers identify any weaknesses in the discs and address them before they are shipped out to customers.

Moreover, suppliers might also test the safety of their products. Since grinding discs can be used in high-speed applications, ensuring they meet safety standards is crucial. Discs are tested to ensure they do not break apart or cause sparks during use, which could lead to injury or damage to equipment. By following safety standards and conducting rigorous tests, grinding disc suppliers ensure that their products are safe for both operators and the equipment being used.

Compliance with Industry Standards

Quality grinding discs suppliers adhere to industry regulations and certifications to ensure their products meet internationally recognized standards. Many suppliers work to meet ISO certifications or other relevant quality standards that validate their commitment to producing high-quality products. By complying with these regulations, suppliers demonstrate their dedication to quality and ensure that their discs meet the expectations of both domestic and international markets.

Grinding disc suppliers rely on a combination of careful material selection, a controlled manufacturing process, rigorous quality testing, customer feedback, and compliance with industry standards to ensure the quality of their products. These practices not only improve the performance and reliability of grinding discs but also contribute to a safer and more efficient working environment. By following these steps, grinding discs suppliers help ensure that their products meet the demands of various industries, delivering reliable and high-performing solutions to their customers.

Eng

Eng  عربى

عربى