Can Flap Discs Factories Support International Shipping?

2025.11.07

2025.11.07

Industry News

Industry News

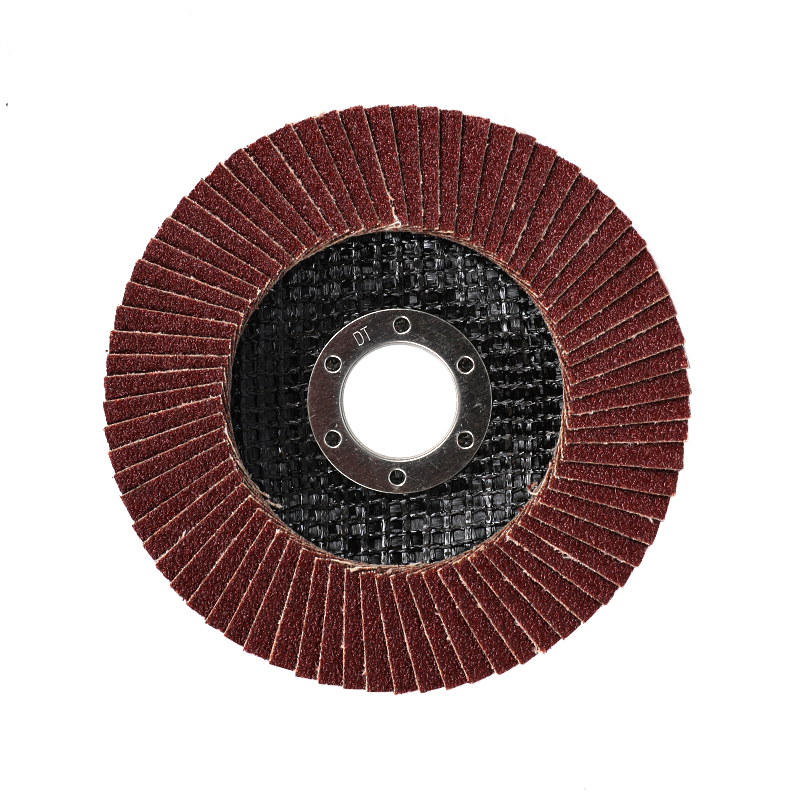

Flap discs are widely used in metalworking and fabrication for grinding, polishing, and finishing surfaces. As demand grows globally, businesses often wonder whether Flap Discs Factories can handle international shipping efficiently. Meeting overseas orders requires careful planning, logistics, and communication.

1. Production Capacity and Readiness

A Flap Discs Factory that supports international shipping must have sufficient production capacity to fulfill large orders. Factories typically produce discs in bulk, with quality control measures in place to ensure consistency. Before shipping internationally, the factory confirms that products meet required specifications, including size, grit, and material type. This preparation ensures that overseas customers receive reliable products without delays or quality issues.

2. Packaging for Safe Transport

One key aspect of international shipping is packaging. Flap discs are abrasive tools, and improper handling can cause damage during transit. Flap Discs Factories usually use sturdy cartons, cushioning materials, and sometimes shrink-wrap to protect each disc. Packages are labeled clearly to comply with customs regulations and reduce the risk of breakage or loss. Proper packaging allows discs to arrive safely at their destination, maintaining their quality and functionality.

3. Shipping Methods and Logistics

Flap Discs Factories often work with logistics providers experienced in international freight. Depending on the order size, discs can be shipped by air, sea, or express courier services. Factories coordinate with shipping companies to choose cost-effective and timely options. They also provide tracking information so buyers can monitor their shipments. By managing logistics professionally, a Flap Discs Factory ensures that international clients receive their orders on schedule.

4. Customs Compliance and Documentation

International shipping involves customs clearance and documentation. Flap Discs Factories must prepare invoices, packing lists, and certificates of origin if required. These documents help avoid delays or additional charges at customs. Factories familiar with export regulations can guide buyers through the necessary paperwork, making the process smoother and reducing potential complications. Clear communication about customs requirements is crucial for successful international deliveries.

5. Communication and Customer Support

Effective communication between the factory and overseas buyers is essential. Flap Discs Factories that support international shipping typically provide updates on production status, shipping schedules, and any potential delays. They may also offer guidance on product selection, quantities, and compliance with local regulations. Responsive support ensures that buyers feel confident in their orders and that any issues are addressed promptly.

6. Considerations for Buyers

When sourcing from a Flap Discs Factory for international orders, buyers should consider lead times, shipping costs, and minimum order quantities. Understanding the factory's export capabilities, packaging standards, and experience with international clients can prevent misunderstandings. Additionally, asking about return policies or defect handling provides extra assurance for long-distance transactions. Choosing a factory that regularly ships abroad increases the likelihood of a smooth and reliable experience.

Flap Discs Factories can indeed support international shipping, provided they have adequate production capacity, proper packaging, logistics management, and experience with export procedures. Buyers who communicate clearly and select factories familiar with overseas delivery can receive high-quality flap discs reliably and on schedule. With careful planning and collaboration, sourcing from a Flap Discs Factory for international markets is both practical and efficient.

Eng

Eng  عربى

عربى