What Are the Benefits of Using Cut Off Grinding Wheels Over Other Cutting Tools?

2025.05.16

2025.05.16

Industry News

Industry News

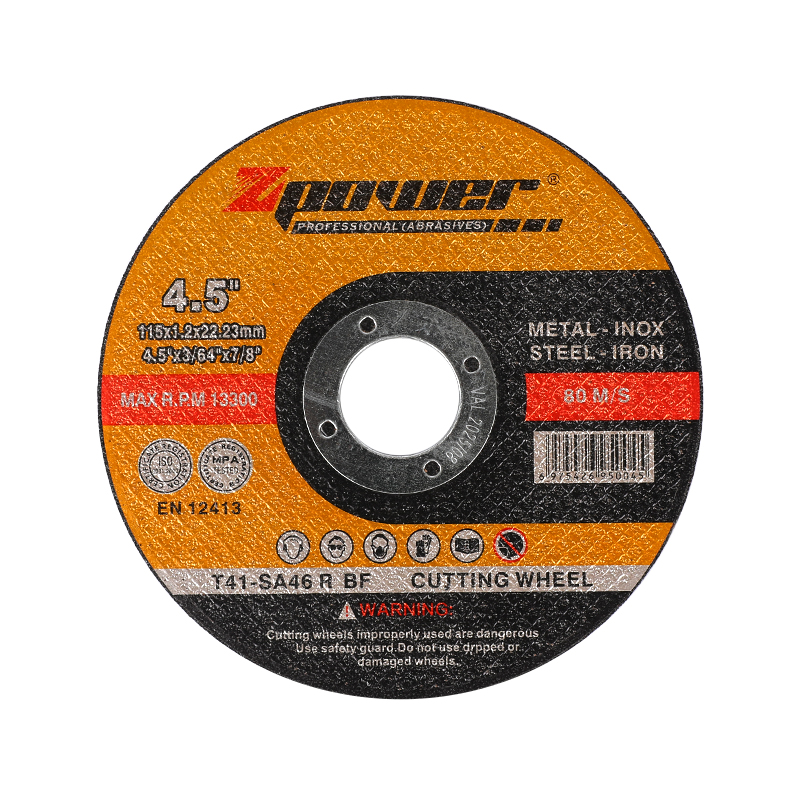

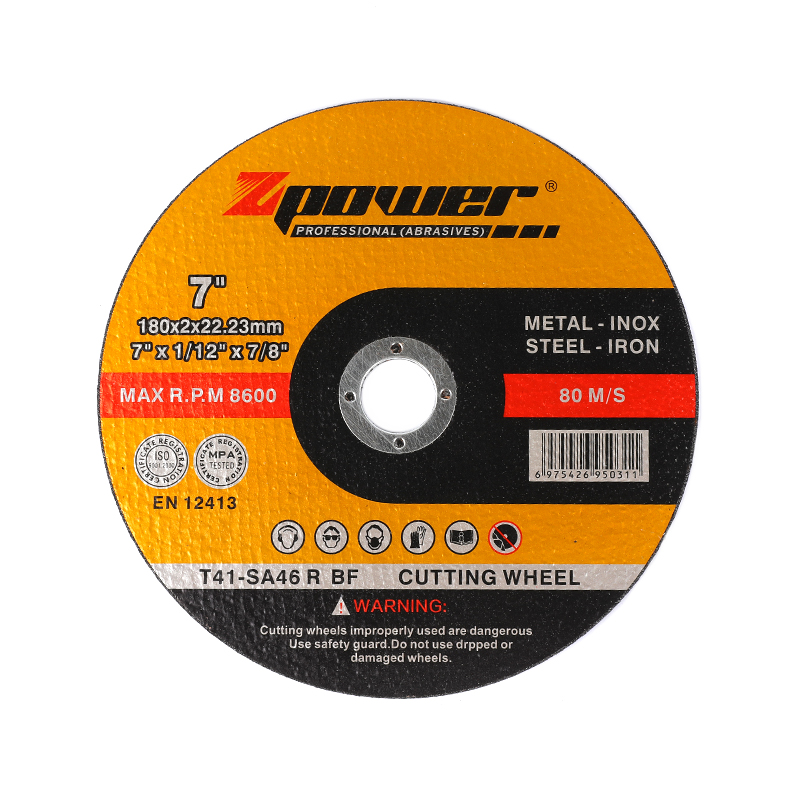

Cut-off grinding wheels are widely used in various industries for precise cutting and grinding tasks, providing an efficient and effective way to work with hard materials like metal, stone, and concrete. These wheels stand out from other cutting tools due to several unique benefits that enhance their performance in demanding applications.

One of the key benefits of using cut-off grinding wheels is their ability to provide precise and accurate cuts. Unlike traditional cutting methods that may result in uneven edges or burrs, cut-off wheels offer a clean and sharp cut. This is especially important in industries like metalworking and construction, where high precision is essential for maintaining the integrity of components and structures. The thin design of cut-off grinding wheels ensures that they make little contact with the material, reducing the risk of distortion or overheating.

Cut-off grinding wheels are designed for high-speed cutting, making them a reliable choice when working with thick or tough materials. Their abrasive properties allow them to quickly slice through a variety of materials, including steel, cast iron, and other metals, as well as stone or ceramics. This high-speed cutting capability reduces the time spent on each task, improving overall productivity. Compared to other cutting tools, such as saws or drills, cut-off grinding wheels can achieve faster results without compromising the quality of the cut.

Another advantage of cut-off grinding wheels is their cost-effectiveness. While other cutting tools may require frequent maintenance or replacement, cut-off wheels typically offer a longer lifespan, especially when used with appropriate materials. Their durable design ensures that they can withstand the rigors of tough cutting tasks without wearing down too quickly. This makes them an economical choice for industries that rely on frequent cutting operations, as they help reduce overall tool replacement costs.

Cut-off grinding wheels are versatile tools that can be used on a wide range of materials, from metals and alloys to concrete and stone. This versatility makes them suitable for various applications across different industries, including automotive, construction, and manufacturing. Whether used for cutting rebar, pipes, or sheet metal, cut-off wheels offer reliable performance for all types of materials. This adaptability makes them a preferred choice for shops and factories where multiple materials need to be processed using the same cutting tool.

When cutting materials with traditional tools like saws, heat can build up in the material, causing deformation or damage. In contrast, cut-off grinding wheels generate less heat during cutting, reducing the risk of heat-affected zones. This makes them ideal for cutting heat-sensitive materials, such as alloys or thin metals, where maintaining the material's integrity is crucial. The lower heat generation also helps extend the lifespan of both the material being cut and the cutting tool itself.

Cut-off grinding wheels are also easier to maintain compared to other cutting tools. With fewer moving parts involved, there is less risk of mechanical failure or wear, making these wheels low-maintenance tools. Their simplicity allows operators to easily replace or change the wheels when necessary without requiring specialized skills or complex procedures. This ease of maintenance contributes to less downtime and more consistent performance on the shop floor.

Cut-off grinding wheels offer several benefits over other cutting tools, including precision, faster cutting speeds, cost-effectiveness, versatility, and minimal heat generation. These advantages make them a valuable tool in various industries, where efficiency, accuracy, and reliability are essential. Whether you are working with metals, concrete, or other materials, cut-off grinding wheels can provide the performance needed to meet the demands of your project. Their durability and ease of use make them an ideal choice for professionals seeking high-quality results in a wide range of cutting applications.

Eng

Eng  عربى

عربى