Why Are Flap Wheel Factories Important for Surface Finishing?

2025.12.19

2025.12.19

Industry News

Industry News

In manufacturing and metalworking, achieving smooth and consistent surfaces is crucial for both functionality and appearance. A Flap Wheel Factory produces specialized abrasive tools designed to polish, grind, and finish surfaces efficiently. These tools are widely used in industries ranging from automotive to furniture production. Understanding the role of a flap wheel factory can help businesses and individual users select the right products for their projects.

What is a Flap Wheel?

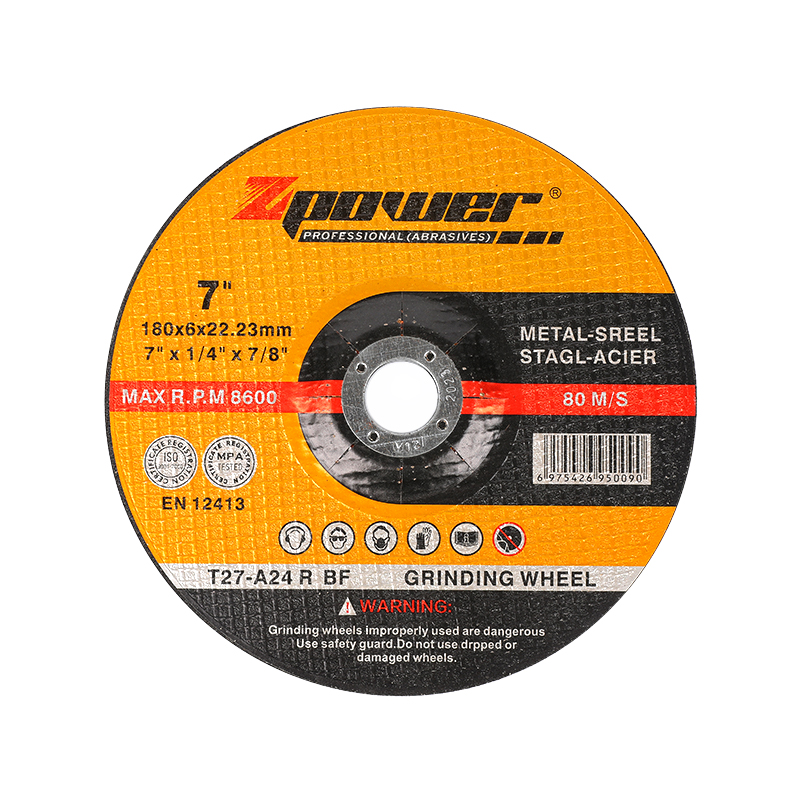

A flap wheel consists of multiple overlapping abrasive sheets attached to a central hub. The design allows the wheel to conform to surfaces, making it suitable for irregular shapes and edges. Unlike traditional grinding wheels, flap wheels provide a finer, more uniform finish, reducing the risk of scratches or uneven surfaces.

How Flap Wheel Factories Operate

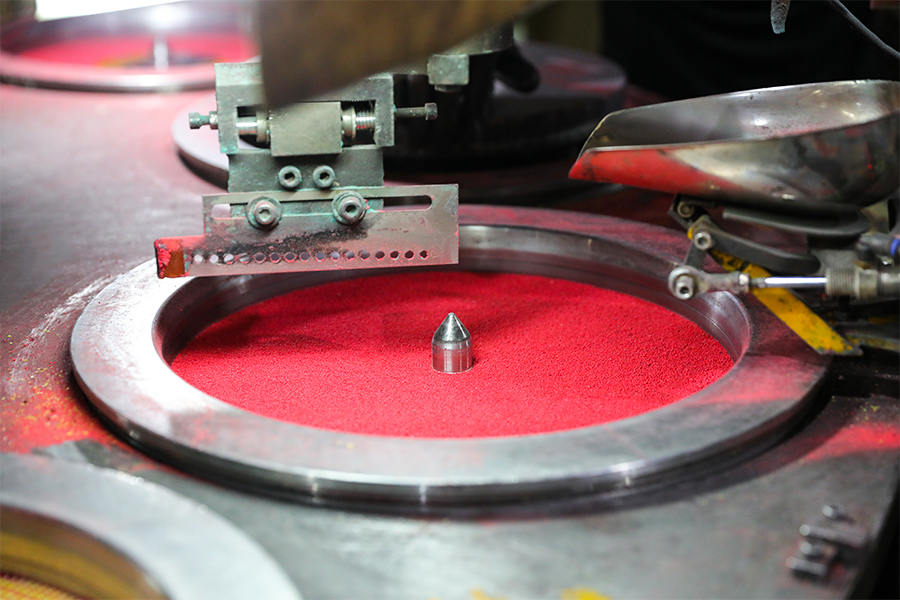

A Flap Wheel Factory typically focuses on producing flap wheels of various sizes, grit levels, and materials to meet the diverse needs of clients. The production process involves selecting high-quality abrasive sheets, precise assembly onto the central hub, and careful quality checks to ensure durability and performance. Factories often offer customization options, such as specific diameters, thicknesses, and types of abrasives, depending on the intended application.

Benefits of Using Flap Wheels

Flap wheels produced by a Flap Wheel Factory offer several advantages:

- Versatility: They can work on metal, wood, plastic, and composite surfaces.

- Consistent Finish: The layered abrasive sheets provide smooth and even surface treatment.

- Efficiency: Flap wheels reduce the time needed for finishing compared to hand sanding.

Edge and Contour Access: Their flexible design allows them to reach corners and curved areas easily.

Choosing the Right Flap Wheel Factory

Selecting a Flap Wheel Factory requires consideration of several factors:

- Experience and Specialization: A factory experienced in producing industrial-grade flap wheels can better meet specific technical requirements.

- Range of Products: Look for a factory that offers a variety of sizes, grit levels, and materials.

- Customization Capabilities: Some projects require specialized wheels for unique surfaces, which a flexible factory can provide.

- Quality Assurance: Factories with stringent quality control ensure that each wheel performs reliably under repeated use.

Applications of Flap Wheels

Flap wheels manufactured in a Flap Wheel Factory are used in many scenarios:

- Metal Fabrication: Smoothing welds, deburring edges, and polishing metal sheets.

- Automotive Industry: Preparing surfaces for painting, polishing engine parts, or finishing body panels.

- Woodworking: Sanding wood surfaces to achieve a uniform texture before finishing.

- DIY and Hobby Projects: Flap wheels are also popular among craft enthusiasts for small-scale metal or woodwork projects.

Tips for Using Flap Wheels Effectively

- Always match the grit size to the task: coarser grit for rough shaping, finer grit for finishing.

- Ensure the wheel is mounted securely on the tool to prevent wobbling.

- Apply consistent pressure during use to avoid uneven wear.

- Replace worn-out flap wheels to maintain performance and safety.

Maintenance and Safety

Maintaining flap wheels from a Flap Wheel Factory is important to extend their lifespan:

- Store in a dry, clean environment to prevent moisture damage.

- Inspect wheels regularly for fraying or damage before use.

- Wear protective gear, such as gloves and eye protection, to avoid injury during operation.

A Flap Wheel Factory plays a vital role in providing reliable and versatile tools for surface finishing. By understanding how these factories operate, the types of flap wheels available, and their practical applications, users can select the right products for industrial, commercial, or personal projects. From smoothing metal surfaces to polishing wooden furniture, flap wheels offer efficiency, consistency, and adaptability, making them an essential tool in any workshop or production line.

Eng

Eng  عربى

عربى