What Makes an Alumina Grinding Wheel Factory Important for Production?

2025.12.25

2025.12.25

Industry News

Industry News

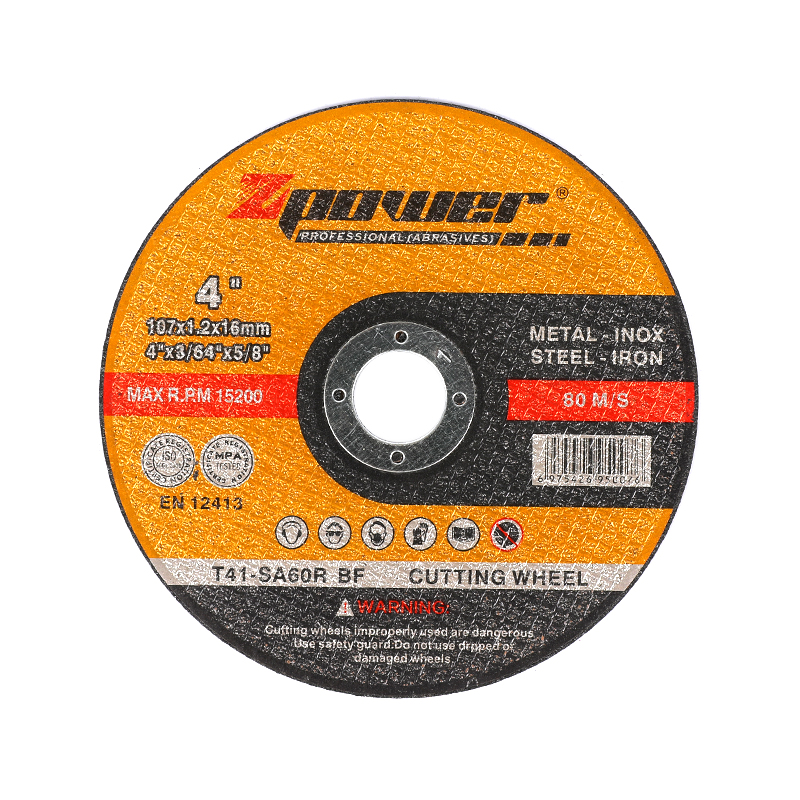

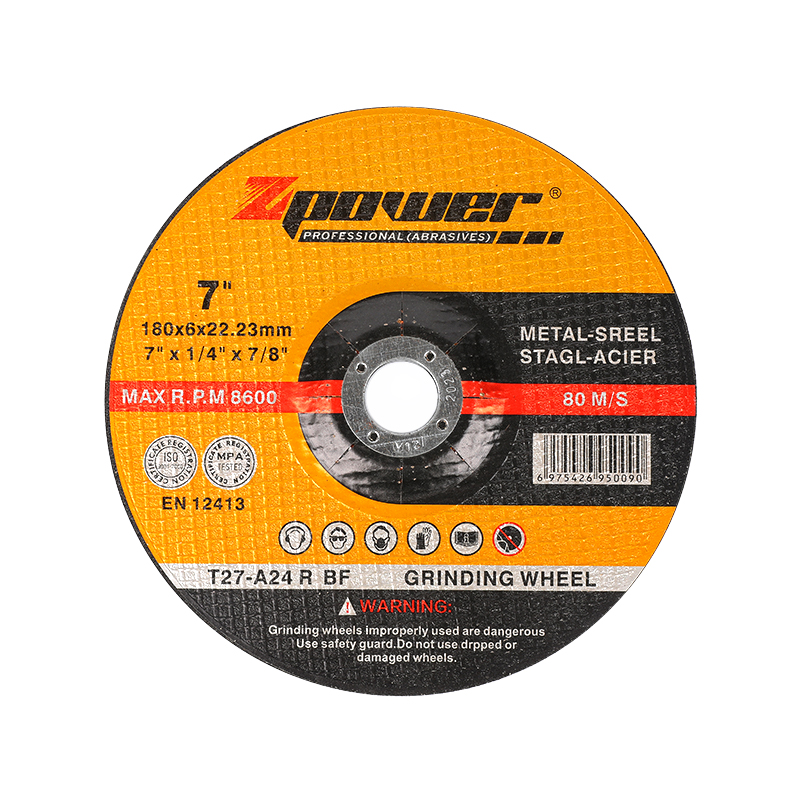

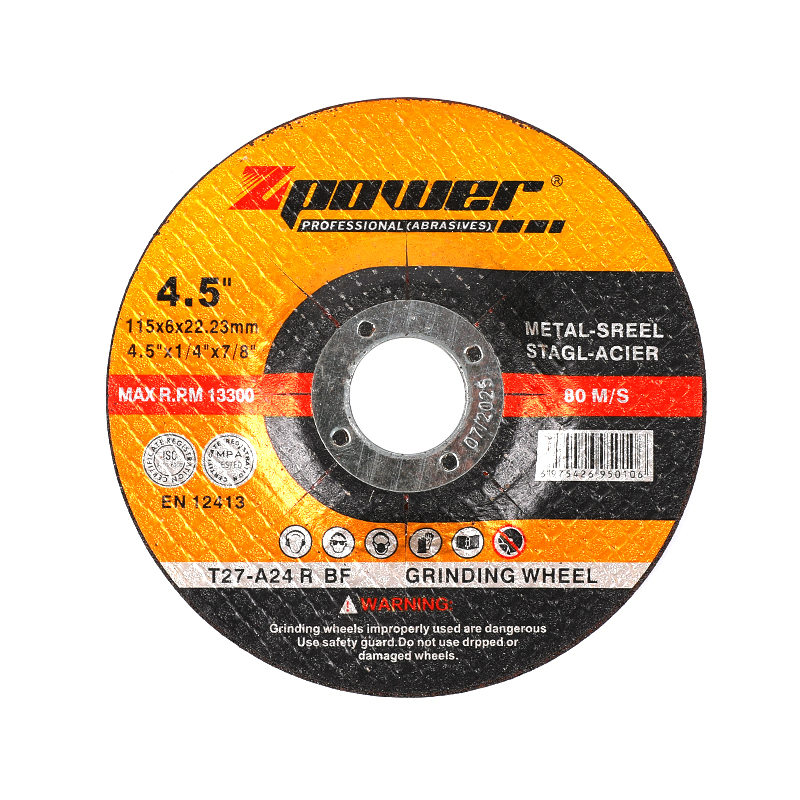

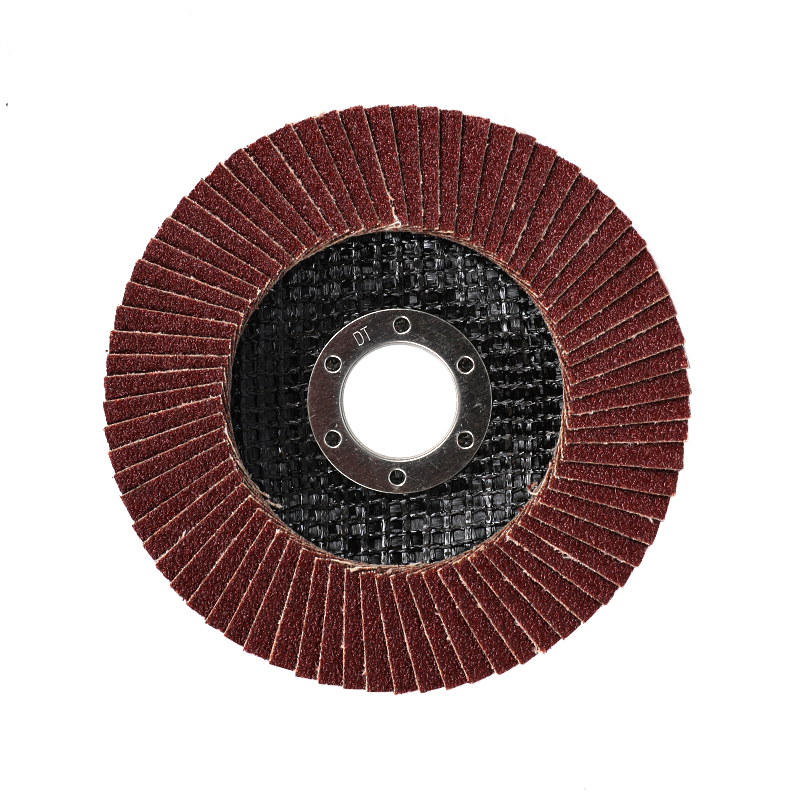

Grinding wheels are essential tools in metalworking, construction, and precision manufacturing. Among them, alumina grinding wheels are widely used for their durability and versatility. Behind the production of these tools is the Alumina Grinding Wheel Factory, which transforms raw materials into functional and reliable grinding products. Understanding the processes, benefits, and considerations involved in such factories can help businesses and industrial buyers make informed decisions.

Material Selection and Design

A key function of an Alumina Grinding Wheel Factory is selecting suitable materials for grinding wheels. High-quality alumina grains are chosen for their hardness and wear resistance. The factory combines these grains with appropriate bonding agents to form wheels capable of handling different types of metals and surfaces. Design considerations also include wheel shape, size, and grit consistency, which influence the performance and longevity of the tool.

Production Process: From Raw Materials to Finished Wheels

The production workflow in an Alumina Grinding Wheel Factory typically involves several stages:

- Mixing: Alumina grains and bonding materials are blended to achieve uniform consistency.

- Molding and Pressing: The mixture is shaped into wheel forms using molds or hydraulic presses.

- Sintering and Firing: Wheels undergo controlled heating to solidify and strengthen their structure.

- Balancing and Finishing: Each wheel is balanced and finished to ensure smooth operation and accurate performance.

- Quality Inspection: Wheels are tested for hardness, uniformity, and durability before being packaged.

This workflow ensures that each alumina grinding wheel meets industrial standards and is ready for professional use.

Applications in Various Industries

Grinding wheels produced by an Alumina Grinding Wheel Factory are widely used across multiple industries. They are applied in metal fabrication for cutting, shaping, and finishing metal surfaces. In construction, they help process concrete and stone. The versatility of alumina grinding wheels makes them valuable for workshops, tool shops, and manufacturing plants, as they provide efficient and consistent results for both heavy-duty and precision tasks.

Advantages for Manufacturers and Buyers

Working with a reputable Alumina Grinding Wheel Factory offers several benefits. Manufacturers can ensure consistent quality across large batches of wheels, reducing operational errors. Industrial buyers benefit from tools that maintain performance over time, which lowers replacement costs and minimizes downtime. Additionally, some factories provide customization options, such as different sizes, grit levels, and bonding types, allowing buyers to obtain wheels tailored to specific applications.

Safety and Maintenance Considerations

Safety is crucial when using alumina grinding wheels. Factories ensure compliance with safety regulations, including proper bonding strength and material quality. Users should follow recommended handling and storage practices to prevent accidents. Regular inspection of the wheels during use is also important to detect cracks, wear, or imbalance that could compromise safety. By adhering to these guidelines, manufacturers and users can maintain both efficiency and safety in operations.

Innovation and Quality Control

Modern Alumina Grinding Wheel Factories often incorporate advanced machinery for consistent production and enhanced quality control. Automated pressing and sintering equipment, along with precise measurement tools, help maintain uniformity in each batch. Some factories also explore new alumina blends or bonding techniques to improve grinding performance, reduce material waste, and extend wheel life. Such innovations support manufacturers in meeting evolving industry demands.

An Alumina Grinding Wheel Factory plays a vital role in the manufacturing and industrial sectors. From material selection and design to production, finishing, and quality control, each step is carefully managed to produce reliable grinding wheels. Businesses and buyers benefit from consistent performance, versatility, and options for customization. Understanding the operation and capabilities of these factories helps users select tools that improve efficiency, maintain safety, and meet diverse application needs.

Eng

Eng  عربى

عربى