What Are the Benefits of Partnering with a Trusted Alumina Grinding Wheel Factory?

2025.07.11

2025.07.11

Industry News

Industry News

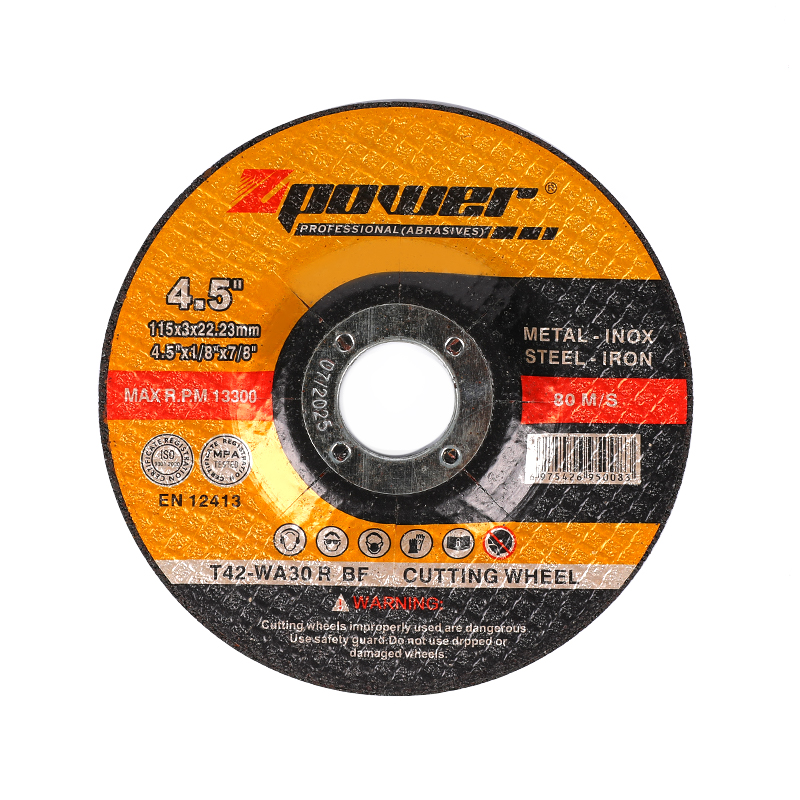

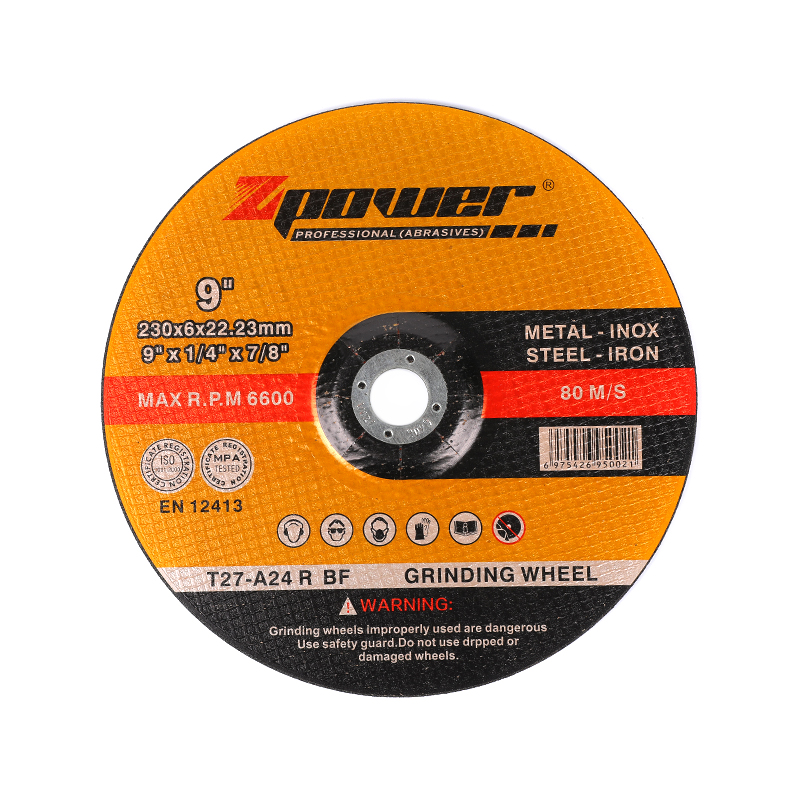

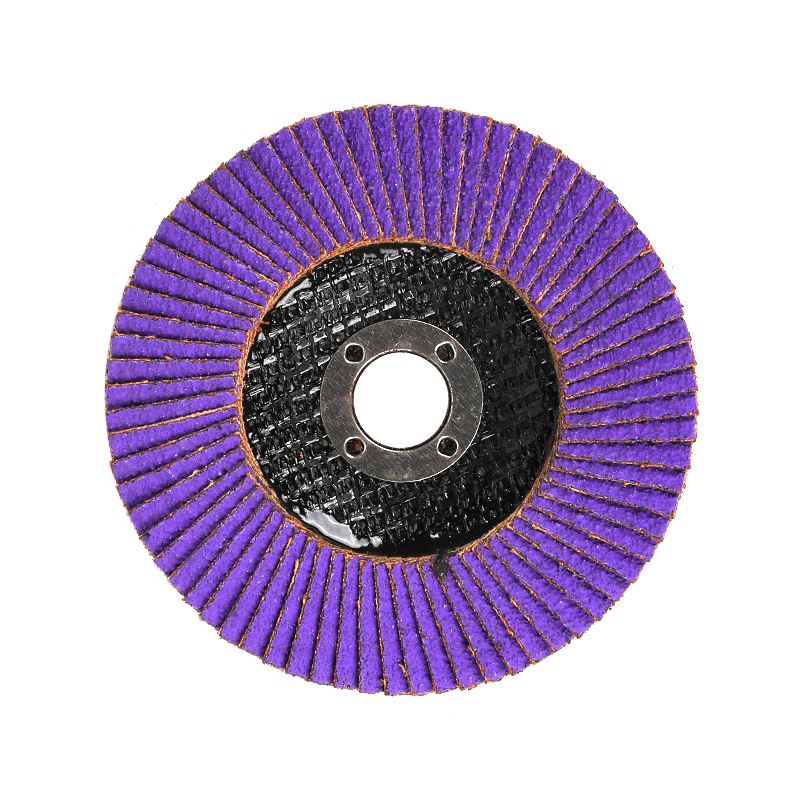

When sourcing abrasive tools for industrial applications, choosing a reliable supplier can make a substantial difference in terms of product performance, consistency, and long-term business relationships. One of the most effective strategies is to collaborate with a trusted alumina grinding wheel factory. These factories typically have the experience, infrastructure, and technical understanding required to support businesses across various sectors, including metalworking, construction, and automotive maintenance.

A major benefit of working with a dependable alumina grinding wheel factory is the assurance of consistent quality. Alumina grinding wheels are used for precision work, where even slight variations in material or composition can impact the result. Factories that specialize in this product category are usually more adept at controlling quality at every stage of the production process—from raw material selection to final inspection. This level of control ensures that each batch meets the necessary specifications, helping your operations maintain a stable level of efficiency and safety.

Another significant advantage is the ability to access technical support and customization options. A seasoned alumina grinding wheel factory can often provide tailored solutions to meet unique project needs. Whether it's adjusting grit size, bond type, or wheel shape, a factory with technical know-how can offer customized products that align with the demands of specific applications. This capability is particularly valuable for manufacturers and workshops that require high precision or work with specialized materials.

Reliable supply chain support is also a critical factor. A trusted alumina grinding wheel factory typically maintains a well-organized production and logistics system. This minimizes delivery delays and helps ensure that clients receive their orders on time. This level of dependability is essential for businesses with tight production schedules, as unexpected delays in tool delivery can disrupt entire workflows and result in financial setbacks.

Collaborating with an established alumina grinding wheel factory often brings cost-efficiency in the long run. While the initial purchase price might not always be the lowest, the overall value is typically higher due to reduced defect rates, lower downtime, and improved product longevity. This cost-effectiveness becomes increasingly apparent over time, especially when considering the cumulative savings from fewer replacements and smoother operations.

Environmental compliance and worker safety standards are also areas where a professional alumina grinding wheel factory can provide added reassurance. Many such factories adhere to industry regulations and standards, using materials and processes that align with environmental and occupational safety requirements. This is crucial not only for regulatory compliance but also for maintaining a responsible brand image and safe workplace environment.

Long-term cooperation with a reliable alumina grinding wheel factory can contribute to better planning and growth. As mutual understanding and trust develop, the supplier may offer insights or innovations that help your business improve productivity. A dependable factory often acts not just as a vendor but as a partner, sharing knowledge and providing updates on material advances, tooling trends, and performance feedback.

Partnering with a trusted alumina grinding wheel factory brings multiple business advantages. These include consistent quality, technical customization, supply reliability, long-term cost savings, safety compliance, and the potential for collaborative improvement. By choosing a factory that understands your operational needs and industry standards, you can build a stable and productive foundation for your abrasive tool sourcing.

Eng

Eng  عربى

عربى