How Do Flap Wheel Factories Maintain Competitive Pricing?

2025.09.05

2025.09.05

Industry News

Industry News

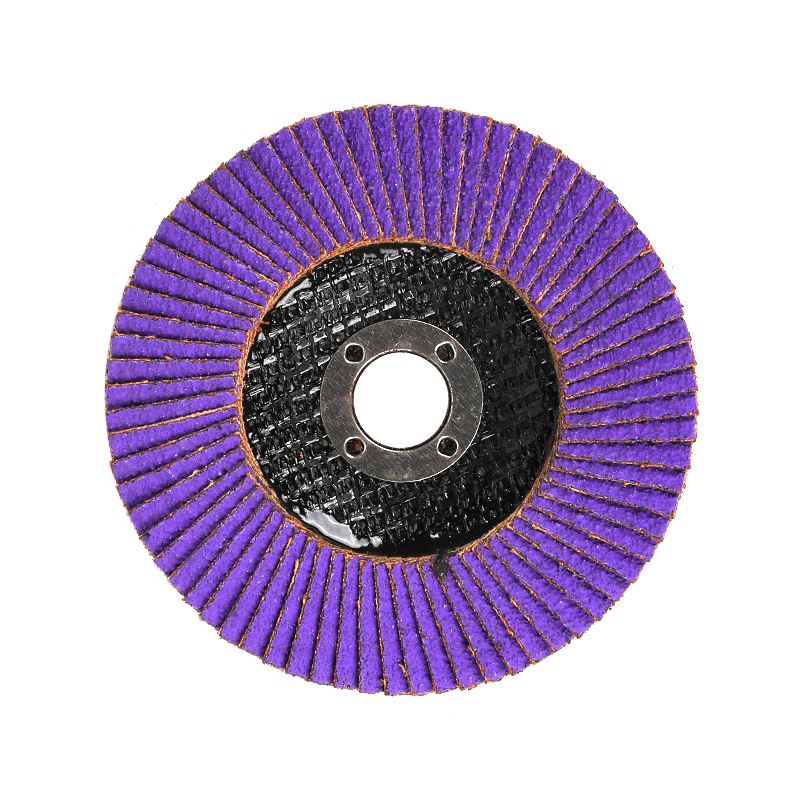

Flap wheels are widely used in metalworking, woodworking, and surface finishing applications. Buyers often compare options not only by quality but also by cost-effectiveness. For this reason, a flap wheel factory must find ways to balance production efficiency, raw material choices, and operational strategies to offer fair pricing while keeping quality standards intact.

Efficient Use of Raw Materials

One of the biggest factors influencing pricing is material selection. A flap wheel factory typically sources abrasive grains, bonding agents, and backing materials in bulk to reduce expenses. By maintaining long-term relationships with suppliers, factories can negotiate more favorable rates and avoid sudden price fluctuations. Additionally, waste reduction during production is prioritized. For example, optimizing cutting and layering processes ensures minimal scrap, which helps control costs without affecting product reliability.

Streamlined Production Processes

Factories that specialize in flap wheels often invest in efficient machinery designed to automate repetitive tasks. By improving production speed and accuracy, labor costs can be managed more effectively. A flap wheel factory may also use modular production systems that allow quick adjustments to different sizes or grit levels without long downtimes. This adaptability saves resources and contributes to stable pricing across a wide range of product variations.

Skilled Workforce and Training

While automation plays a role, skilled workers remain essential for overseeing quality and fine adjustments. To maintain competitive pricing, factories invest in training programs that improve employee efficiency. A well-trained workforce reduces errors, lowers rejection rates, and ensures consistency. Over time, these improvements help a flap wheel factory control hidden costs that might otherwise increase product prices.

Economies of Scale

Producing flap wheels in large volumes provides a natural cost advantage. A flap wheel factory operating on a larger scale spreads fixed expenses such as machinery investment, facility maintenance, and energy consumption across a higher output. This approach lowers the per-unit cost of each flap wheel, enabling the factory to offer competitive pricing without compromising production standards.

Focus on Supply Chain Efficiency

Another way factories control costs is by optimizing their supply chain. Strategic decisions, such as locating production facilities near material suppliers or shipping hubs, can reduce transportation expenses and delivery times. A flap wheel factory that manages logistics effectively avoids unnecessary overhead and passes part of these savings on to customers through fair pricing.

Balancing Cost and Quality

Competitive pricing is not simply about lowering expenses. Buyers expect durability and consistent performance. Factories therefore strike a balance by maintaining quality checks at different production stages. This approach reduces the risk of customer complaints or product returns, which can be more expensive than investing in proper inspection. By preventing such setbacks, factories ensure that pricing remains fair while protecting long-term customer trust.

The ability of a flap wheel factory to maintain competitive pricing comes from a mix of strategies: smart material sourcing, efficient production systems, skilled labor, economies of scale, and supply chain management. These efforts ensure that buyers receive reliable flap wheels at reasonable costs. For both industrial users and distributors, understanding these practices highlights how factories manage the delicate balance between affordability and quality.

Eng

Eng  عربى

عربى